Choosing to reshore or nearshore your operations isn’t one-size-fits-all. What makes sense for one company may not make sense for another.

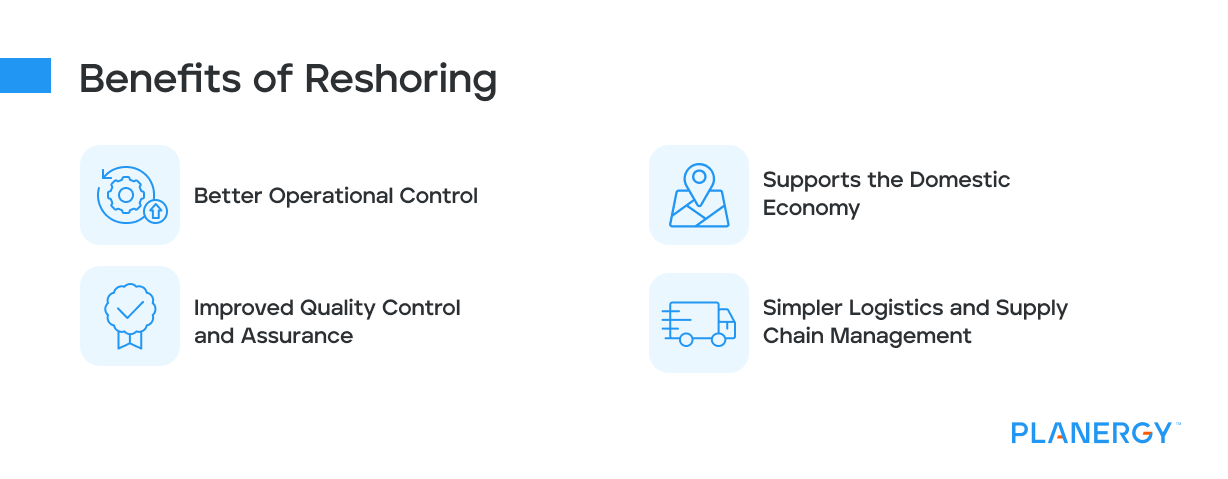

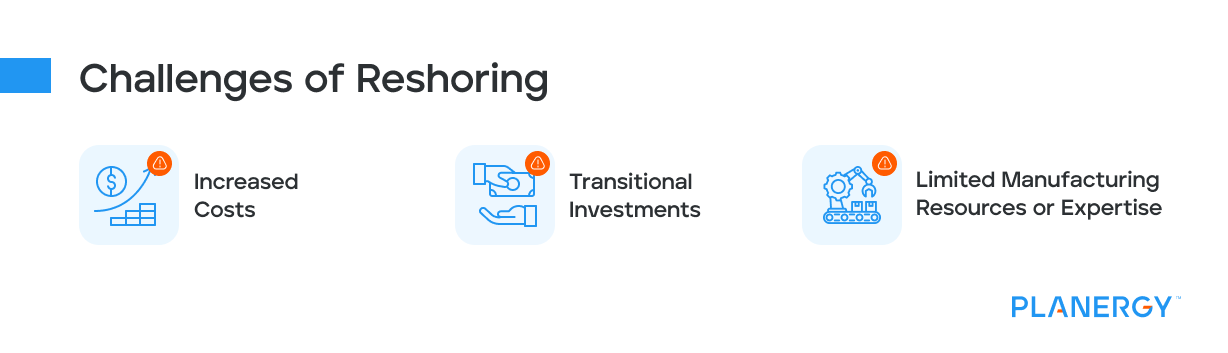

Cost Efficiency: Savings on shipping and reduced supply chain risk can help offset the higher labor expenses associated with reshoring.

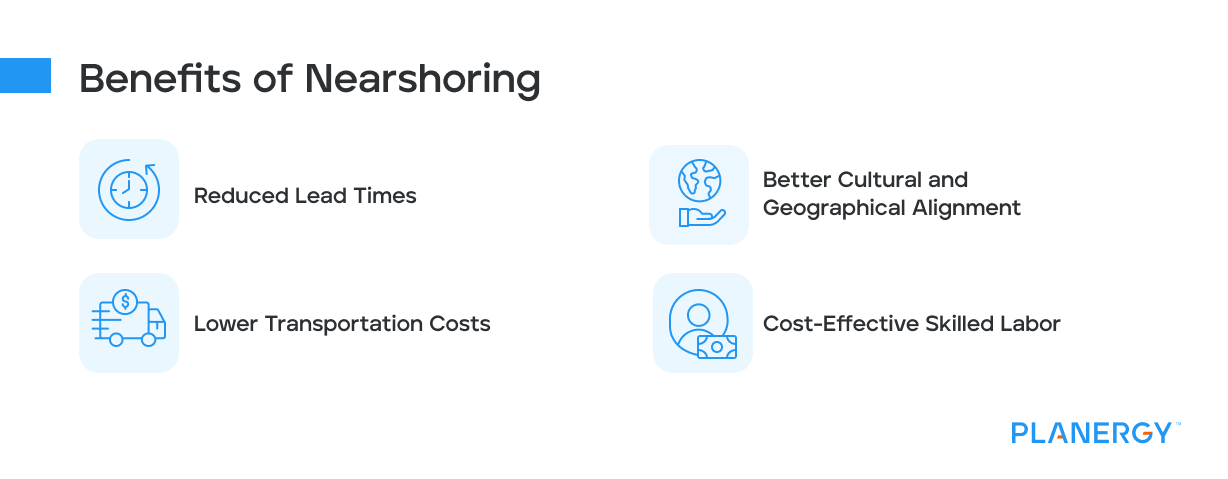

Nearshoring makes it easier to strike a balance between affordable labor and reduced logistics expenses.

Supply Chain Resilience: Reshoring eliminates global transport uncertainties and provides complete control over production.

Nearshoring facilities regional supply chain continuity without compromising too much on cost.

Speed and Agility: Reshoring allows quicker responses to changing market needs because your production is fully localized.

Nearshoring shortens the delivery timeline compared to traditional offshore sourcing while maintaining regional flexibility.

Sustainability Goals: Reshoring helps reduce carbon emissions by cutting global shipping.

Though nearshoring doesn’t have quite the same environmental impact, it still helps since it shortens transportation distances.

Consider Your Industry

Depending on your industry, your unique operational needs may mean one option clearly stands out over the other.

In healthcare and pharmaceuticals, you need strict oversight for safety, compliance, and quality.

In aerospace, the high standards for precision mean you need tight control over your production chain.

In businesses that can maximize artificial intelligence and automation, the machinery offsets labor costs.

Nearshoring is likely to be the better option for industries requiring manual labor, such as customer service or textile manufacturing.

Determine Your Priorities

Whether your supply chain is successful depends on your highest priorities, no matter if it is proximity, cost efficiency or agility.

Regardless, you must know your inventory management needs.

Using tools like economic order quantity (EOQ) helps ensure you maintain an optimal balance between ordering costs and inventory holding costs, which is especially significant when deciding between reshoring or nearshoring.

If high operational control and oversight are priorities, then reshoring creates the environment for stricter monitoring.

But, if agility in meeting regional demand takes precedence, nearshoring gives you quicker market access, making inventory flow and order fulfillment more adaptable to fluctuations.

Customer Location

Placing production facilities closer to your customer base can improve delivery times, save money, and improve satisfaction.

If you have short inventory cycle times, reshoring ensures faster alignment between production and final delivery, so you have stock levels that are responsive to customer demand.

If you have a diverse regional customer base, you can leverage nearshoring to establish efficient inventory hubs closer to your key markets.

Effective inventory management flows—from demand forecasting to warehouse distribution—can support nearshoring efforts, enabling you to scale your operations while remaining responsive to local markets.

Conduct a Cost Analysis

Labor costs undoubtedly influence supply chain decisions, but the total cost of production considers many other factors.

Reshoring may mean you spend more money on labor, but it can also reduce spending in hidden areas like long shipping routes, delays, and global trade risks.

Businesses that emphasize reducing their cash conversion cycle may benefit from reshoring, since it helps minimize the time it takes to convert inventory into revenue.

Evaluate Regulatory Factors

Compliance rules such as tariffs, trade agreements, and labor laws heavily influence where you produce and source materials.

When transitioning operations, businesses that rely on electronic transactions must also verify compatible payment systems for financial operations.

Using electronic payments in reshored or nearshore facilities ensures efficient, secure transactions within your supply chain.

Similarly, switching to electronic funds transfer (EFT) methods simplifies cross-border payments for businesses nearshoring to neighboring nations like Mexico or Canada.