A strong procurement function is a key requirement for business success. Organizations need robust processes and strategic relationships with goods and service providers to bring about optimal growth, profitability, and seamless business operations.

While many organizations have focused primarily on direct procurement (or direct spend) – acquiring goods, services, and any essential supplies or raw materials used to create a final product – indirect procurement has often been overlooked for optimization.

To harness the value hidden in indirect procurement, organizations need to reimagine their current processes.

By combining approaches traditionally only applied to direct spend, with change management, and advanced technologies, procurement professionals can integrate process optimization, strategic spend management, and better supply chain management into their indirect procurement workflows.

What Is Indirect Procurement?

Indirect procurement is focused on sourcing and purchasing products and services that support a business’s operations but are not directly impacting the core revenue creating activities of creating and delivering the product or service the business sells to it’s customers.

Direct procurement relates to the purchasing of products and services that are directly involved in creating the product or service you deliver to your customers.

The indirect/direct model historically was applied very easily to companies that manufacture physical items, whether that is a loaf of bread, a piece of medical equipment, or a building.

Classifying spend as direct or indirect has become increasingly less straightforward with the increasing importance of the service economy.

Indirect procurement (or indirect spend) involves optimizing the acquisition of products and services that support an organization’s day-to-day operations, but do not play an essential role in the creation of final products or services delivered to customers.

Indirect spend often accounts for 25% or more of a company’s entire procurement. Indirect procurement provides the foundation for “the business of doing business”.

Indirect Procurement Examples

Indirect spend may include:

- IT services

- SaaS subscriptions

- Uniform supplies

- Food and travel

- Janitorial Services

- Human Resources

- Facilities management

- Marketing and advertising

- Utilities (water, electricity, etc.)

- Office supplies and equipment (lighting, printers, etc.)

- Maintenance, Repair, and Operations (MRO)

- Outsourced professional services (security, accounting, etc.)

What Is The Difference Between Indirect and Direct Procurement?

The key difference between direct and indirect procurement is how the items being sourced will be used.

Direct procurement focusses on core supplies that will be used to deliver goods or services to your customers. Indirect procurement focusses on items that support your business functions but are not directly used in the goods or services you supply to generate revenue.

Historically, energies were focused on optimizing direct procurement with strategies like strategic sourcing. Indirect procurement was largely left unmanaged and covered by ad-hoc or decentralized processes.

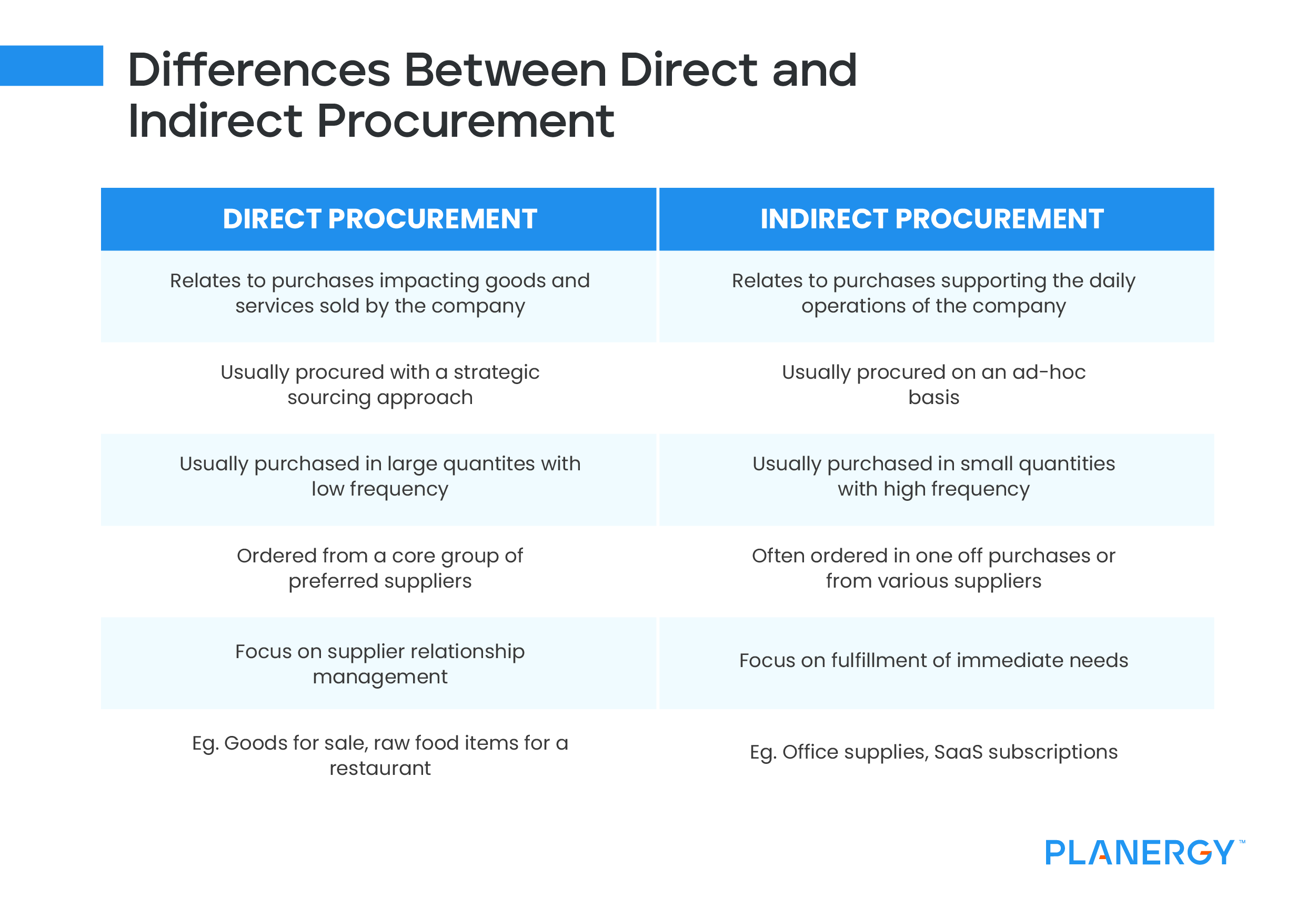

| Direct Procurement | Indirect Procurement |

|---|---|

| Relates to purchases impacting goods and services sold by the company | Relates to purchases supporting the daily operations of the company |

| Usually procured with a strategic sourcing approach | Usually procured on an ad-hoc basis |

| Usually purchased in large quantities with low frequency | Usually purchased in small quantities with high frequency |

| Ordered from a core group of preferred suppliers | Often ordered in one off purchases or from various suppliers |

| Focus on supplier relationship management | Focus on fulfilment of immediate needs |

| Eg. Goods for sale, raw food items for a restaurant | Eg. Office supplies, SaaS subscriptions |

The Problem with Indirect Procurement Processes

Companies have often prioritized direct procurement in the procurement function, seeking to maximize efficiency, cost savings, and value when sourcing raw materials and essential services.

Indirect procurement has been left relatively unmanaged often with negative impact on service delivery and cost effectiveness.

In addition, despite the growing importance of digital transformation to competitive strength, many companies continue to rely on manual workflows and paper-based processes in procurement, and in particular for indirect procurement.

As a result, companies lose value in numerous ways due to:

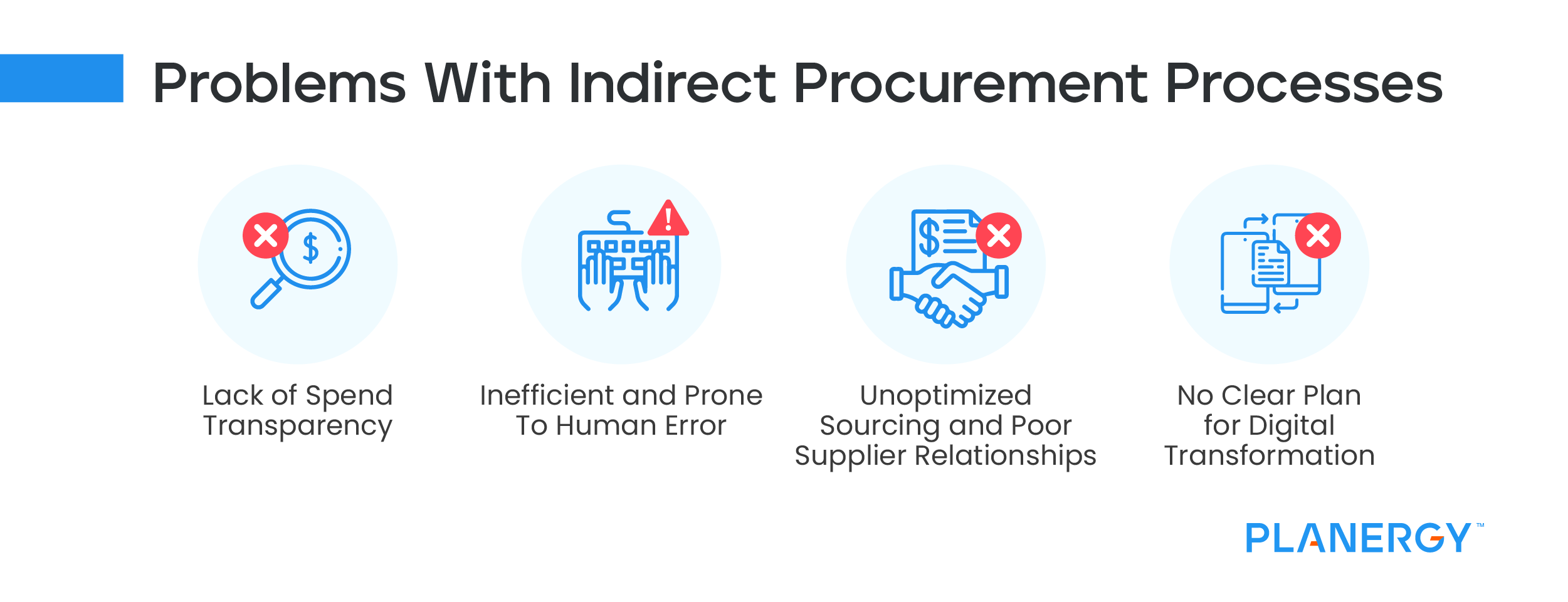

Lack of Spend Transparency

Without full spend transparency and process-driven accountability, companies increase their risk exposure through higher rates of maverick spend, invoice fraud, and even theft.

Inefficiency and Human Error

Manual workflows are tedious, repetitive, and susceptible to human error, which then adds additional costs by requiring time-consuming investigation and correction.

They also increase overhead cost and reduce efficiency, since procurement and accounts payable professionals have to spend time and energy on relatively low-value tasks rather than supporting strategically valuable initiatives.

Unoptimized Sourcing and Poor Supplier Relationships

Too often, only direct materials vendors receive the time and attention required to build strong and strategic supplier relationships.

Indirect procurement teams, meanwhile, are instructed to focus solely on quick cost savings opportunities, and therefore miss out on greater value in strategically sourcing indirect goods and professional services.

No Clear Plan for Digital Transformation

Organizations mired in the paper-and-pencil past and traditional approaches that prioritize direct procurement alone may struggle to secure interest, let alone approval, in making the digital leap.

Such organizations need not only new tools, but a proactive plan for effecting cultural change to make modernization and digitization possible—and ensure everyone from the C-suite down is engaged, educated, and working toward the same goals.

By relegating indirect procurement to the back burner while continuing to rely on outdated processes and technology, companies are limiting their own growth, functionality, and bottom line.

The “Focus” Shift in Procurement

Every organization will require a mix of indirect and direct procurement strategies to function optimally. However, there has been a shift with indirect spend taking up a larger and larger percentage of business spend.

With many organizations operating digitally, selling as-a-Service software products and other intangibles, procurement teams are slowly shifting more focus to indirect spend.

Strategies used in direct procurement combined with modern technology can help businesses realize significant savings.

Indirect spend can account for 25% or more of a company’s entire procurement, with optimization cost savings of 10-25% can be realized.

The Benefits of Managing Indirect Procurement

With the increasing importance oo indirect procurement, it’s important for organizations to understand the benefits of properly managing and optimizing indirect spend – via digitization and automation. Here are some of the key benefits:

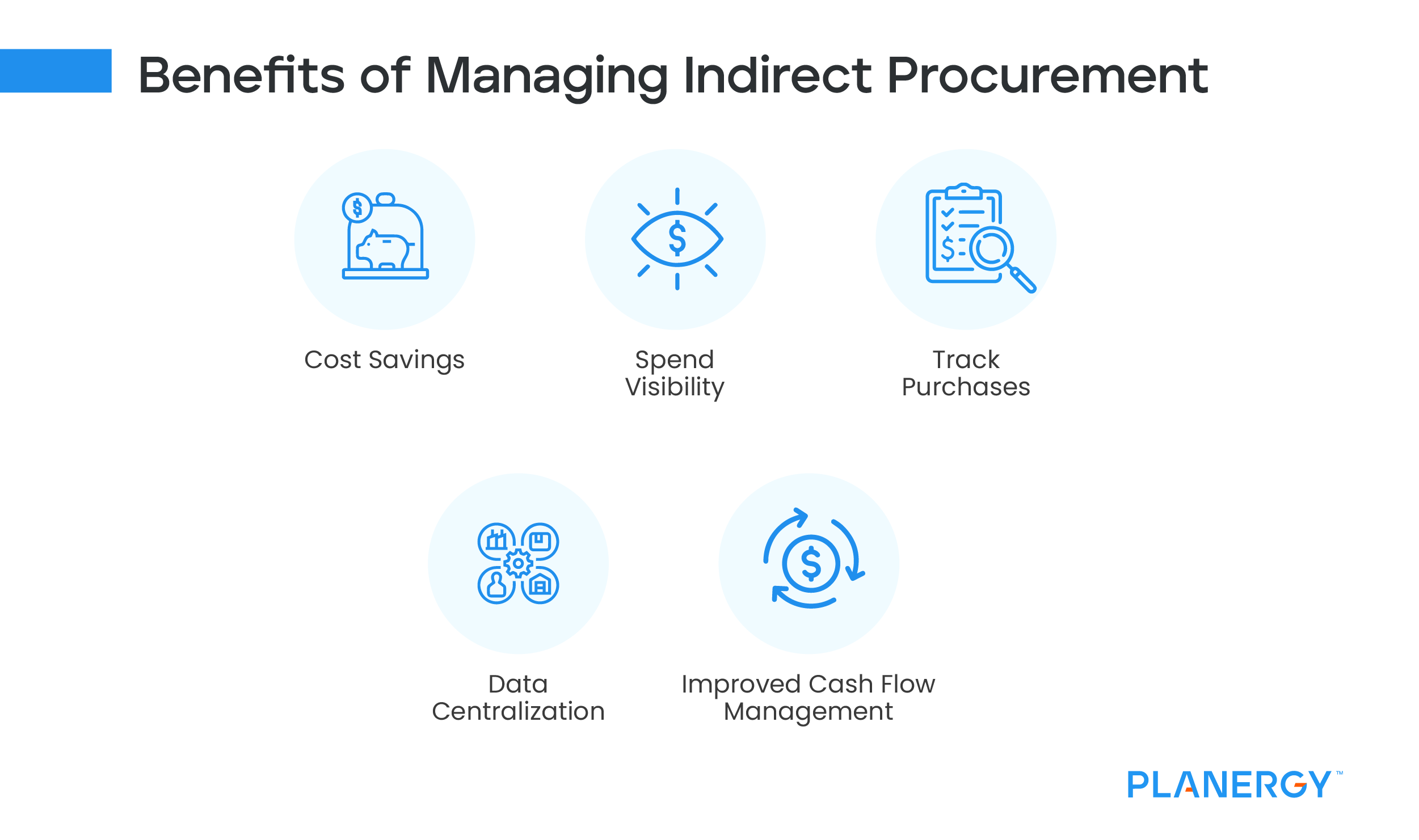

Cost Savings

Managing indirect spend can reduce product and service costs by 10-25%, according to McKinsey and Company.

Having access to data, organizations gain insights to partner with high-performing, cost-effective suppliers – enabling cost-effective ordering.

Spend Visibility

Given the stakeholders and processes involved with enabling procurement, transparency and being able to account for every cent is essential for making improvements, problem-solving, and acquiring a general understanding of fiscal health.

Further, these elements can improve overall efficiency, efficacy, and accuracy of an organization, specifically if the goal is to scale.

Track Purchases

A lot of time is wasted chasing up on purchases internally and with suppliers. If staff can be given the ability to track purchases through the process it can reduce time-consuming back and forth queries.

How much money is being spent? Who are the vendors being used? Which employees are making purchases?

Using an automated solution like PLANERGY, tracking indirect procurement with the same level of scrutiny used to track direct spend will increase accountability, and streamline purchase requests, approval workflows, and expense requests.

Data Centralization

Having accessible data in one location offers comprehensive visibility into an organization’s indirect spend with risk analytics, spend analytics, detailed audit trails, and budget insight at decision points.

Improved Cash Flow Management

Leveraging an automated procurement solution allows organizations to take control of their indirect spending by ensuring approvals and spending compliance, maintaining budgets, and eliminating rogue spend.

How To Effectively Manage Indirect Procurement

Typically involving several stakeholders, contracts to negotiate, and spend categories, indirect procurement can be a complex process to manage, regardless of industry.

However, by incorporating a few essential steps, companies can achieve a proactive indirect procurement process that reduces expenditures and saves time.

Here are some tips to better manage indirect procurement:

Improve Supplier Relationship Management

Effective supplier relationship management, open communication, and a friendly, collaborative approach are crucial in creating opportunities to partner with quality suppliers to ensure your requirements for compliance, efficiency, and spend management are met.

Leveraging long-term supplier relationships to get the best quality materials at the best price. Mutually beneficial supplier relationships can also be helpful in achieving effective contract management and category management.

Focus On Change Management

Education and ensuring you take everyone with you is key to the success of any large change in business operations and improving indirect procurement processes is no different. A change management plan can help ensure a smooth transition.

Refreshers on internal procurement controls, best practices, and the nature of indirect spend, along with informational seminars can help bring everyone onto the same page.

It is also a good idea to cultivate relationships and collaborate with stakeholders on activities related to indirect procurement. They will likely be well-versed in the nitty-gritty details because of their direct work in the field.

Obtaining their valuable insight will enable companies to solve problems and predict financial patterns quicker and more accurately.

Lastly, if you are implementing an E-procurement solution, be sure to train and educate staff ahead of any upgrades to allow staff to familiarize themselves with new procurement processes and their specific roles within them.

Encourage Responsible Spending

Maverick spending can cause hiccups and confusion within the procurement processes, increase risks of fraud and non-compliance, and negatively impact an organization’s bottom line.

But, it may be an opportunity to bring about awareness and raise questions – Why is this happening? Which spend categories are suffering the most from maverick spending? Who are the mavericks?

Further, through strategic dialogue, it is essential to educate stakeholders and staff members on the need to adhere to procurement procedures and implement the necessary framework to guide their purchasing decisions.

Invest in Digital Transformation

Optimizing and digitizing internal processes for indirect procurement will save considerable time and introduce much needed procurement agility.

To gain true visibility, transparency, and control over indirect spend, companies should invest in spend management software, such as PLANERGY. This will help eliminate time-consuming manual processes that are prone to human errors.

Digital procurement will allow procurement teams to:

- Streamline workflows

- Improve category management

- Build customized reports to assist in forecasting and budgeting

- Gain real-time, company-wide visibility on all procurement activities and the business units they support

With accessible insights and data, and a transparent indirect procurement process, companies can drive organizational change, while gaining insights to collaborate with high-performing, cost-effective suppliers.

This gives way to the consolidation of purchase orders and bulk purchases to yield improved financial value for the overall organization.

Leverage Spend Analytics Insights

With better spend visibility and reporting it becomes possible to identify opportunities for savings through measures like supplier consolidation, contract negotiation, and smarter buying to leverage quantity discounts.

Risk Management

With centralized data you can also manage risk much more effectively. Problems in how you deliver your goods or services can impact your reputation just as much as the quality of the goods and services themselves.

Minimizing or eliminating risk exposure in your indirect procurement can help ensure business processes remain optimized.

This can also focus on compliance with ESG strategies. Ethical practices extend to your indirect procurement suppliers. If these are not managed correctly this could impact on customer satisfaction.

The Future of Indirect Procurement: Blending Basics with Next-Gen Tech

Representing over a quarter of a company’s entire procurement, indirect procurement is about much more than office supplies; maintenance, repairs, and operations (MRO); or janitorial services.

Yet, it remains an afterthought in most organizations, which is both unfortunate and costly – research from McKinsey and Company found indirect procurement optimization can reduce organizational costs by 15 to 17 percentage points.

Today, effective indirect procurement management is increasingly focused on three core concepts:

Applied Procurement Fundamentals

Procurement, centered around obtaining and purchasing goods and services, involves several interconnected processes. To remain competitive, financially healthy, and ensure business continuity, companies must follow best practices for these processes.

Procure-to-Pay Optimization

Optimization that includes both indirect and direct spend, and is executed using digital tools:

Provides guided purchasing, informed by strategic spending and category management policies, ensuring full visibility and accountability, while decreasing the risk of fraud and maverick spend.

Supports business continuity and long-term supply chain resilience through data-driven supplier management for indirect spend categories using key performance indicators (KPIs) and analytics.

Improves cash flow through full spend transparency, and more strategic and robust supplier relationships; AP can capture more early payment discounts, leverage economies of scale, or preserve capital as needed.

Allows indirect procurement teams to use and benefit from the same supplier and category management tools and strategies as direct procurement.

Effective Category Management

Category management can be a major companion to indirect spend management. Expertise and stronger engagement with suppliers, combined with granular indirect spend data, allows procurement teams to secure optimal pricing and terms, streamline supply chain efforts, and develop contingencies as needed.

Additionally, granular data provides valuable analytical insights that can be used to adjust forecasts, identify opportunities to further improve workflows, or decide whether to outsource essential support services such as information technology (IT) or maintain them in-house.

Strategic Use of Metrics

Data is crucial to improving both indirect and direct procurement. Measuring performance and compliance, along with tracking and evaluating KPIs with concise data, procurement teams can easily streamline supply chain by replacing non-mutually beneficial supplier relationships with more ambitious ones.

Zero-Based Budgeting (ZBB)

ZBB requires justification of every dollar spent. It works best when budgets are set by using rich data streams, the expertise of indirect spend category managers, and a shared commitment to supporting financial, departmental, and/or project goals.

Prioritizing Agility and Resilience

Focusing on creating agile and resilient procurement in your organization can also be a powerful tool in modernizing your indirect procurement (and procurement in general). Agility uses cross-functional collaboration to bring together skilled experts from multiple business units, disciplines, and backgrounds.

These teams apply their expertise and skills to manage categories proactively and flexibly, based on insights gleaned from data analytics, performance metrics, and financial strategies.

This allows them to manage indirect spend from a much broader perspective in real time so they can take advantage of cost savings opportunities or secure value by lowering total cost of ownership through strategic partnerships for indirect goods used across multiple departments and budgets.

Applied Digital Technologies

Companies that invest in and implement digital procurement solutions such as PLANERGY can enhance their workflows with automation, AI, and analytics to support optimization of existing procurement processes, and integrate new procurement strategies necessary to modernize and digitize indirect spend.

Automation

Automation provides powerful and immediate benefits in optimizing indirect procurement and the entire P2P process. Software bots require minimal oversight, eliminate human error, and have the ability to integrate rules and policies set by procurement and finance teams to automatically ensure spend remains within budgetary parameters.

Advanced Analytics and Centralized Data Management

Combined with integrating procurement with your existing software environment provides improvements like:

Fully transparent connections between budget planning and actual spend.

Elimination of data silos and file format conflicts.

Provide support for advanced analytics tools that project demand, suggest supply chain consolidations, and provide insights, allowing procurement teams to seize unique opportunities such as cross-category purchasing initiatives.

Artificial Intelligence

Artificial intelligence is essential to digitization, can be trained, over time, to evaluate its own efficiency and efficacy, integrating continuous improvement into all workflows. AI can be as basic or as advanced to meet an organization’s specific needs.

Further, advanced AI also drives analytics and advanced purchasing processes.

Combining indirect spend data, the Internet of Things (IoT), and automatic replenishment tools, today’s procurement teams can rely on software to automatically track inventory and automatically move inventory to fill needs or place orders for new items – complete with context-aware contingencies that route requests falling outside the budget to a human approver for review.

Reap the Benefits of Digitizing Indirect Spend Processes

While managing indirect procurement can be a challenge for companies of all sizes, it is critical to an organization’s overall success and their bottom line.

However, lack of visibility and transparency, maverick spending, inefficient processes, human errors, and poor supplier relationships can lead to significant waste, missed cost savings and value improvement opportunities.

Proactive organizations and procurement teams can eliminate these challenges by implementing eProcurement technologies, such as PLANERGY, and combining them with clear procurement goals and a strategic approach to procurement fundamentals. In turn, improving overall processes, productivity, and profitability.