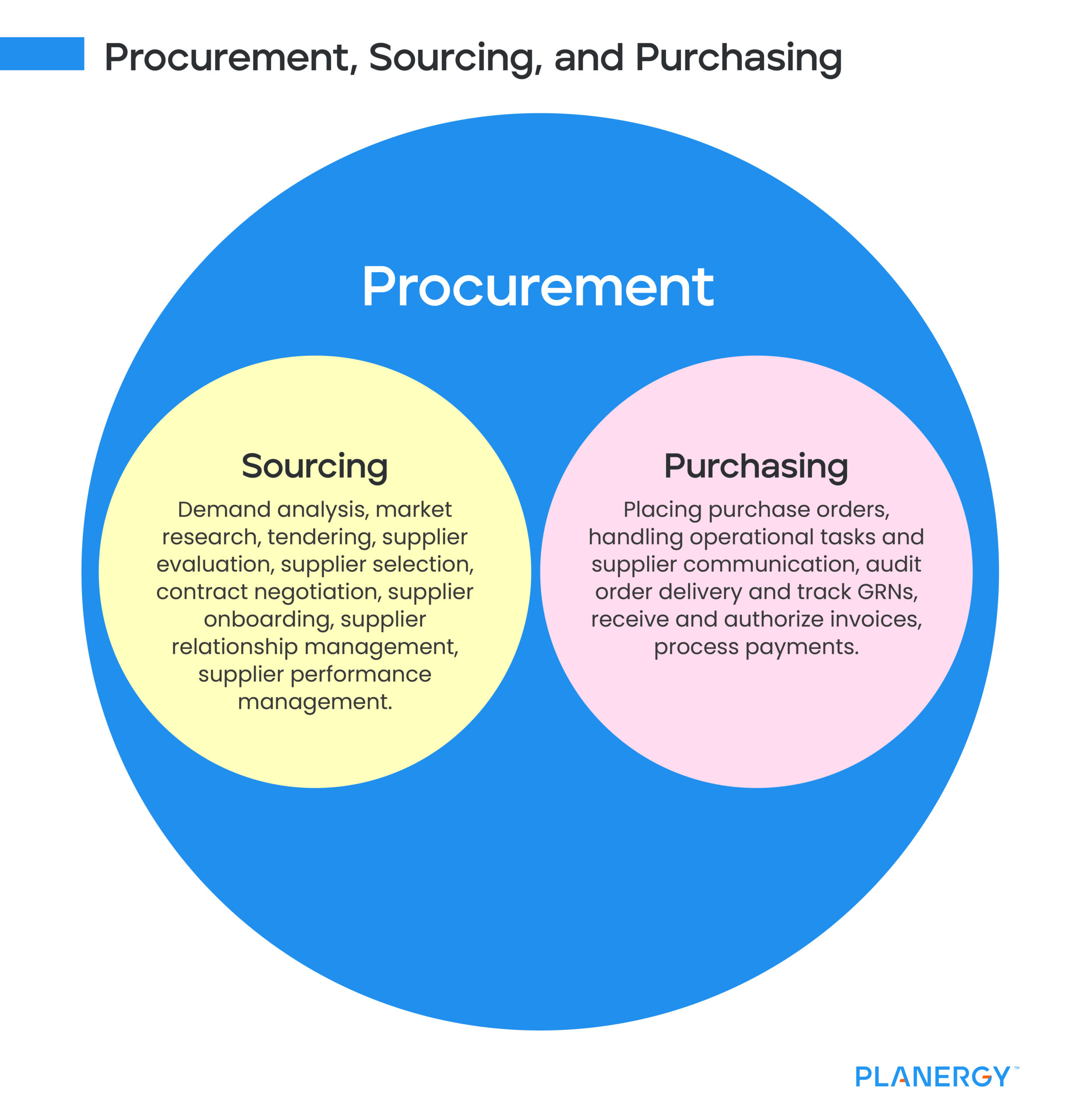

Much like procurement and supply chain management, procurement and sourcing are two related but different terms that are often used interchangeably. Sourcing is actually a part of procurement, but not the whole.

Let’s take a look at the difference between the two so you can better understand which term should be used and when.

What is Procurement?

Procurement is the process of gathering the materials you need for your products and services through suppliers. Procurement departments place orders with suppliers, receive goods, and pay for them.

Procurement is an end-to-end process that covers activities like planning, negotiating pricing, purchase requisitions, purchase orders, and inventory control.

Procurement starts the supply chain process because once the materials you need for manufacturing are in place, you can begin making the products you sell to others.

Without a solid procurement strategy, there’s always a chance that operations could grind to a halt. If you can’t get access to the materials you need to make a product, then you must stop production until a suitable alternative is developed.

Is Procurement the Same As Purchasing?

Procurement and purchasing are not the same. Purchasing is part of the overall procurement process that has multiple steps, with purchasing as the final step.

Purchasing involves placing purchase orders with the suppliers, getting order confirmation, following up with suppliers until delivery, and then ensuring invoices get paid.

Why Is Procurement Sometimes Called Sourcing?

While procurement and sourcing are not the same thing, they are closely related, which leads to some confusion over which is which.

Sourcing is part of the overall procurement process.Sourcing includes finding and vetting suppliers but not actually purchasing the materials and services you need to run your business.

What Is Sourcing?

Sourcing is the group of procurement activities related to identifying and assessing potential suppliers; and selecting and managing suppliers to ensure best value for your company.

Before you can procure materials from your suppliers, you must first find and vet those suppliers.

When you have an effective sourcing process, you’ll find reliable, affordable, and quality suppliers to provide the goods you need.

This might also include screening for compliance with your company policies, such as your ESG procurement strategy. Due diligence here makes the overall procurement function more streamlined and efficient.

Sourcing is a balancing act between quality and affordability. The less you can spend on materials, the more profit your business can earn. But, if you are too cheap and buy shoddy materials, your product becomes worse. Your customers want quality, too!

Sourcing includes requesting quotes, obtaining vendor information, determining lead time, setting up contracts, pricing, minimum order quantities, and more. This is done one time for each supplier except when updating pricing information.

Sourcing teams are always busy because it’s important to have backup suppliers in case one falls through.

During sourcing, you must assess your purchasing needs, map out a plan, conduct market research, and identify potential suppliers. After that, you’ll then evaluate the suppliers and choose the most suitable one for your needs.

Repeat the process for all other purchasing needs until you have suppliers for everything.

Procurement is the overall process of getting the materials you need. Sourcing is finding and vetting the suppliers of those materials. Sourcing is the part of the procurement process that happens before purchasing can take place.

What Is the Difference Between Sourcing and Procurement?

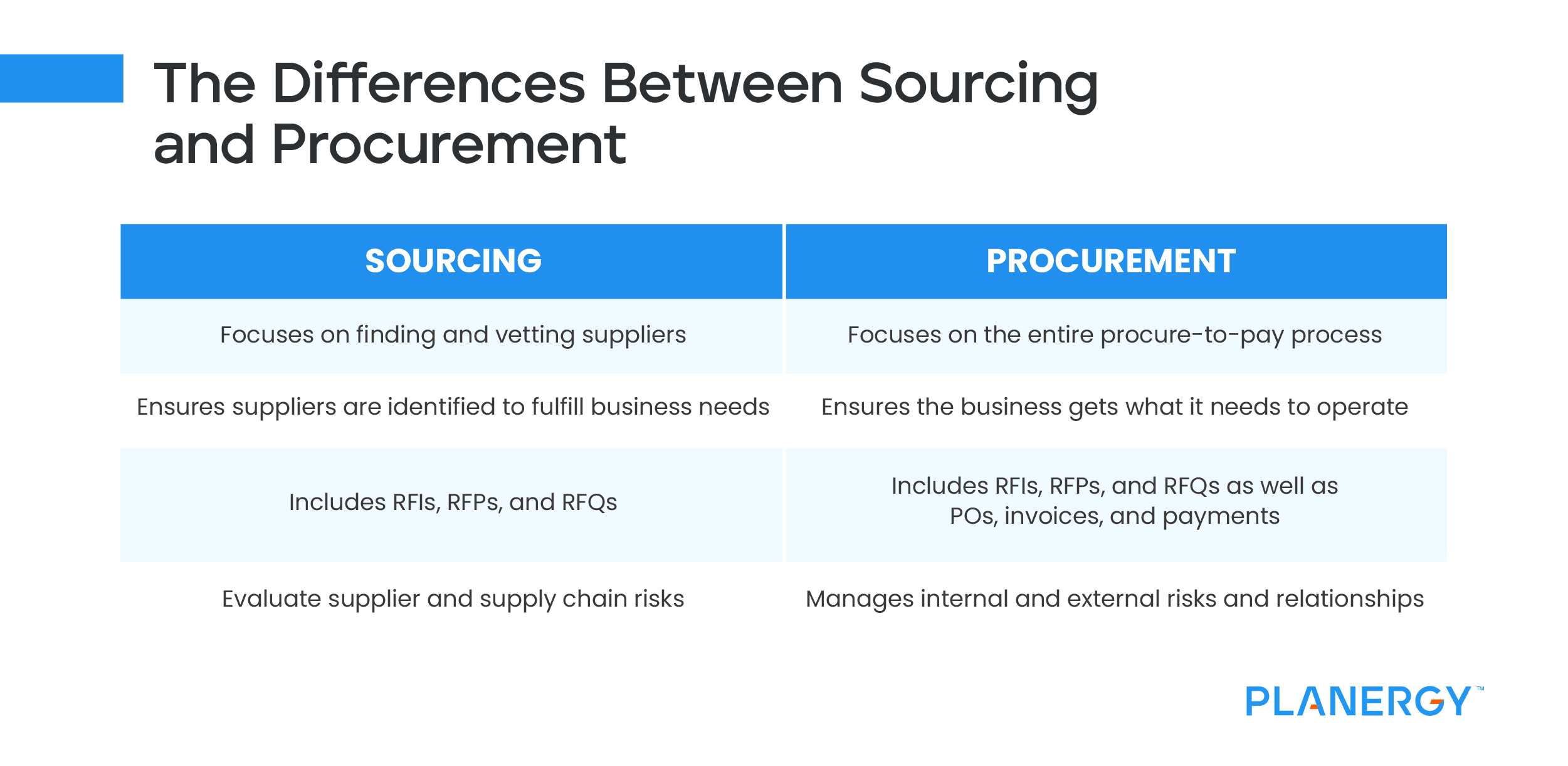

The main difference between sourcing and procurement is that sourcing focuses purely on suppliers, while procurement also focuses on purchasing. Sourcing is a subset of the procurement process and happens before a company makes purchases.

Sourcing teams analyze supplier lists and performance while paying close attention to the risk each supplier poses. Sourcing is most concerned with how to get products that meet all business needs—time, quality, location, and quantity—at the best price.

Procurement is a larger process that begins with sourcing and goes all the way through payment and supplier relationship management.

It seeks to maximize value through the entire procure-to-pay process, maintain relationships with the best suppliers, and minimize risk throughout the supply chain.

| Sourcing | Procurement |

|---|---|

| Focuses on finding and vetting suppliers | Focuses on the entire procure-to-pay process |

| Ensures suppliers are identified to fulfill business needs | Ensures the business gets what it needs to operate |

| Includes RFIs, RFPs, and RFQs | Includes RFIs, RFPs, and RFQs as well as POs, invoices, and payments |

| Evaluates supplier and supply chain risks | Manages internal and external risks and relationships |

There is often some overlap between sourcing and purchasing. Both departments negotiate pricing and payment terms, communicate with suppliers, and ensure company needs are met.

What Is Strategic Sourcing?

Strategic sourcing refers to adopting various sourcing strategies and models to minimize risks and costs while increasing purchase value.

Strategic sourcing considers the overall needs of a company strategically, instead of focusing on individual sourcing requirements tactically, to realize better value across the organization.

Strategic sourcing is crucial to a company’s development because it helps negotiate the best price and quality—directly influencing profit margin and net income.

Like sourcing, strategic sourcing is also a part of the procurement process. It employs higher-level strategies around sourcing to help companies optimize for better deals and higher qualities on the goods and services they need to conduct business.

What Are Some Benefits of Strategic Sourcing?

Strategic sourcing works to find the best suppliers, quality, and price for the goods and services your business needs. Its benefits include:

- Long-term cost savings

- Better quality raw materials

- Stronger supply chain risk management

- Increased supply chain sustainability

- Better understanding of the market

- Increased negotiating power

What Are the Steps of the Strategic Sourcing Process?

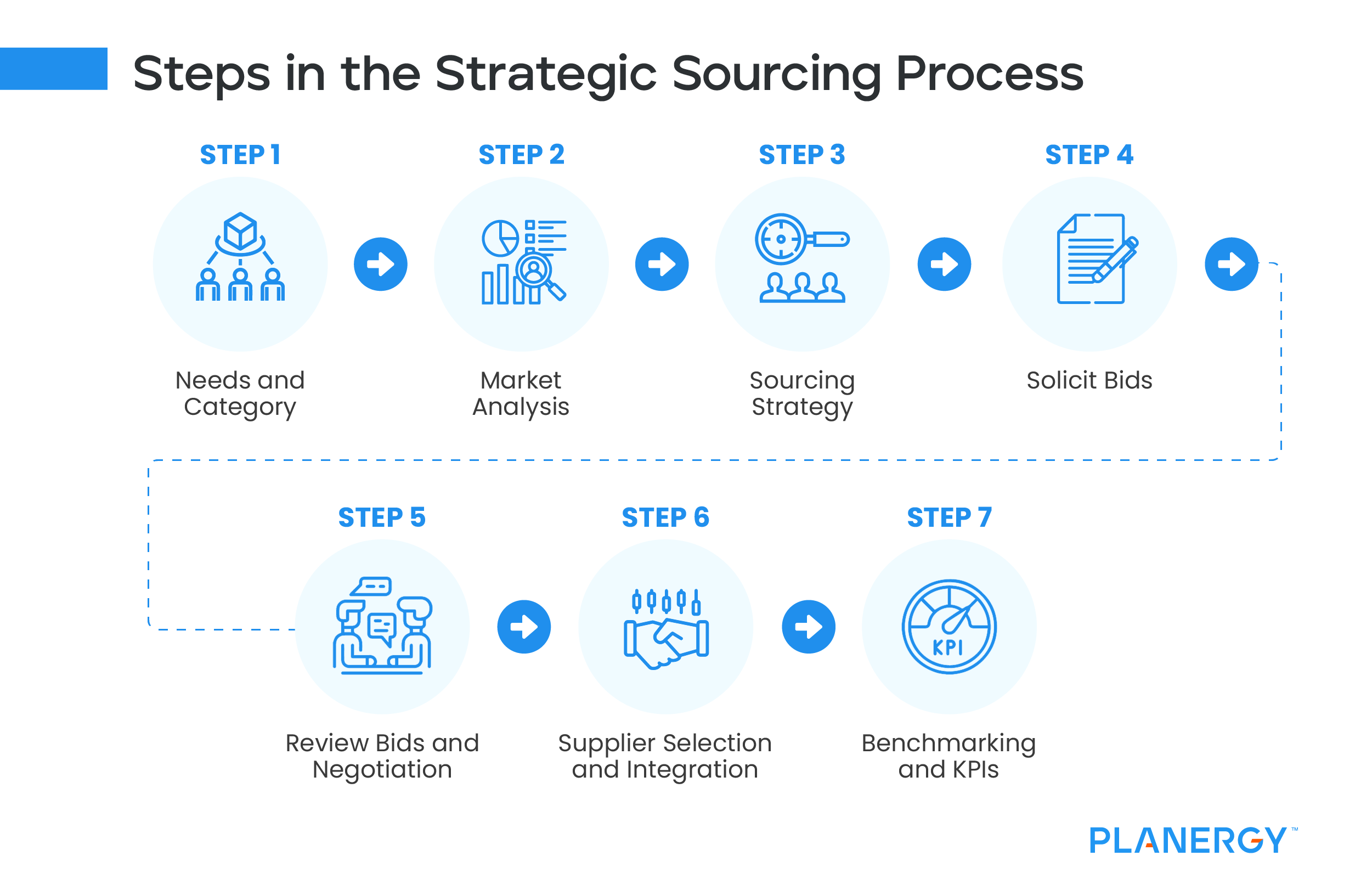

The steps of the strategic sourcing process help companies measure a supplier’s impact on their business and weigh that against other suppliers and market conditions. These steps include:

-

Needs and Category

In order to get a feel for fair pricing and quality, it’s important to create a category for the products and services you need. You can bucket vendors into different categories and start to identify average prices and trends within those categories.

You’ll also need to understand internal needs and how they match up against these categories. Figure out what goods and services you need, how much, and what the supply chain looks like. Category management in procurement has many benefits.

-

Market Analysis

Analyzing the market is key to understanding your negotiating power and how suppliers can impact your business. When looking at suppliers in each category, identify areas where you take on risk and other areas where your profitability could be impacted. This analysis can be used to help you negotiate contracts with suppliers.

-

Sourcing Strategy

Your sourcing strategy is a set of criteria that you need potential suppliers to fulfill. To create this strategy, examine when and where you need goods and services, how much you’ll need, how to minimize cost and risk, and how you can create a stable supply chain. You should have clear business goals that suppliers can meet.

-

Solicit Bids

Now that you have conducted a market analysis and have clearly defined criteria, you can solicit bids from potential suppliers. This involves sending a request for quote (RFQ) or a request for proposal (RFP). These documents outline the criteria laid out in your sourcing strategy and go into detail on your exact requirements.

-

Review Bids and Negotiation

From the list of suppliers that responded to your RFQ or RFP, you can start gathering more information. This involves asking for clarification on any outstanding questions, figuring out which suppliers pose a greater risk for disruption, and making sure you understand pricing and discounts.

The more information you get the more balanced your selection decision can be and the more negotiating power you will have.

Once you’re satisfied with the responses and information, you can start negotiating. Based on what you know, you can ask for better payment terms, early payment discount opportunities, lower prices, and other perks.

-

Supplier Selection and Integration

After negotiating, you can choose the supplier that meets your criteria for the best price, quality, and other benefits they provide. Once selected, you’ll need to integrate the supplier into your procurement process.

This can involve setting up a contract, entering them into your procurement system, and anything else that gets you ready to purchase. You’ll also want to establish communication protocols and key points of contact to ensure issues can be quickly addressed.

-

Benchmarking and KPIs

Once you start buying from a supplier, you need to make sure they’re continually meeting or exceeding your expectations. Using key performance indicators (KPIs) such as on-time delivery and quality control measurements helps you measure their performance over time.

At the beginning of your relationship with a supplier, you can set a benchmark of what you expect from them, and then use the KPIs to measure against that to ensure they continually deliver.

Improving Sourcing and Procurement Through Automation

Automating the procure-to-pay process with procurement software makes the procurement processes smoother and more effective. Tracking supplier performance and KPIs, maintaining supplier relationships, and gaining access to early payment discounts is easier when it’s automated.

Procure-to-pay software like PLANERGY also integrate with your ERP and other software systems, which makes it easy to track and share integral data throughout related business processes.