Like life itself, procurement is an inherently risky endeavor. Suppliers can fall short in quality, quantity, or timeliness.

Rogue spending and fraud can erode your profits without being detected until it’s too late. Internal processes may not be optimized, resulting in costly errors and exceptions.

And at the end, you’re the one left holding the proverbial bag. As a result, procurement risk management is a key part of effective and strategic sourcing.

Managing risk within your supply chain might seem daunting.

But with the proper procurement processes in place, the right technological tools at your disposal, and a well-informed, carefully planned risk mitigation strategy, you can take control of your supply chain management, reduce or eliminate dangerous potential risks, and generate both cost savings and measurable value for your business.

What Are Procurement Risks?

Procurement risks refer to potential issues that can disrupt the procurement process, leading to delays, increased costs, or compromised quality of goods and services.

These risks can arise from various sources, including suppliers, internal processes, market conditions, and geopolitical factors.

Effective procurement risk management helps organizations minimize these disruptions and maintain a resilient supply chain.

Importance of Risk Management in Procurement

You can have the best procurement team that has conducted due diligence before onboarding new suppliers.

They may have a stellar supplier performance record, but risks will always exist.

And if you don’t manage them proactively, you could be looking at major reputational damage and hits to your bottom line.

Cost Control

Unmanaged risks can lead to unexpected costs, impacting the organization’s budget and profitability.

For example, sudden price hikes in raw materials can drastically increase production costs if not anticipated and managed effectively.

Operational Continuity

Identifying and mitigating risks ensures that the procurement process runs smoothly, avoiding production or service delivery interruptions.

A disrupted supply chain can halt operations, leading to significant financial losses and customer dissatisfaction.

Quality Assurance

Managing risks helps maintain the quality of procured goods and services, which in turn affects the overall quality of the product or service.

Poor-quality materials or components can lead to defective products, recalls, and brand reputation damage.

Supplier Relationships

Proactive risk management fosters stronger supplier relationships by addressing potential issues before they escalate.

Suppliers appreciate being part of a transparent process where risks are communicated and managed collaboratively.

7 Common Procurement Risks

Supplier Reliability

Dependence on a single supplier or unreliable suppliers can lead to supply disruptions.

If a key supplier fails to deliver on time, it can cause production delays and financial losses.

Diversifying the supplier base can mitigate the potential for supply chain disruptions.

Compliance Issues

Failing to adhere to regulations and standards can result in legal and financial penalties.

This includes compliance with environmental regulations, labor laws, and industry-specific standards.

Regular audits and staying updated with regulatory changes are essential.

Market Fluctuations

Changes in market prices for raw materials can significantly affect procurement costs.

Volatility in commodity prices or exchange rates can lead to budget overruns. Hedging and long-term contracts can help stabilize costs.

Geopolitical Risks

Political instability or trade restrictions in supplier countries can disrupt the supply chain.

Events such as tariffs, sanctions, or political unrest can impact the availability and cost of goods. Developing a risk-aware sourcing strategy is vital.

Quality Risks

Poor-quality products from suppliers can affect the quality of the end product.

Implementing strict quality control measures and setting clear contract quality expectations can help manage this risk.

Regular supplier evaluations are also crucial.

Logistical Risks

Transportation delays or failures can hinder the timely delivery of goods.

Natural disasters, strikes, or logistical inefficiencies can affect the supply chain.

Building flexibility into logistics plans and having alternative transportation options can be beneficial.

Procurement Fraud

Unethical practices such as bribery, kickbacks, or inflated invoicing can lead to significant financial losses.

Establishing strong internal controls, regularly auditing procurement activities, and fostering a culture of transparency can mitigate these risks.

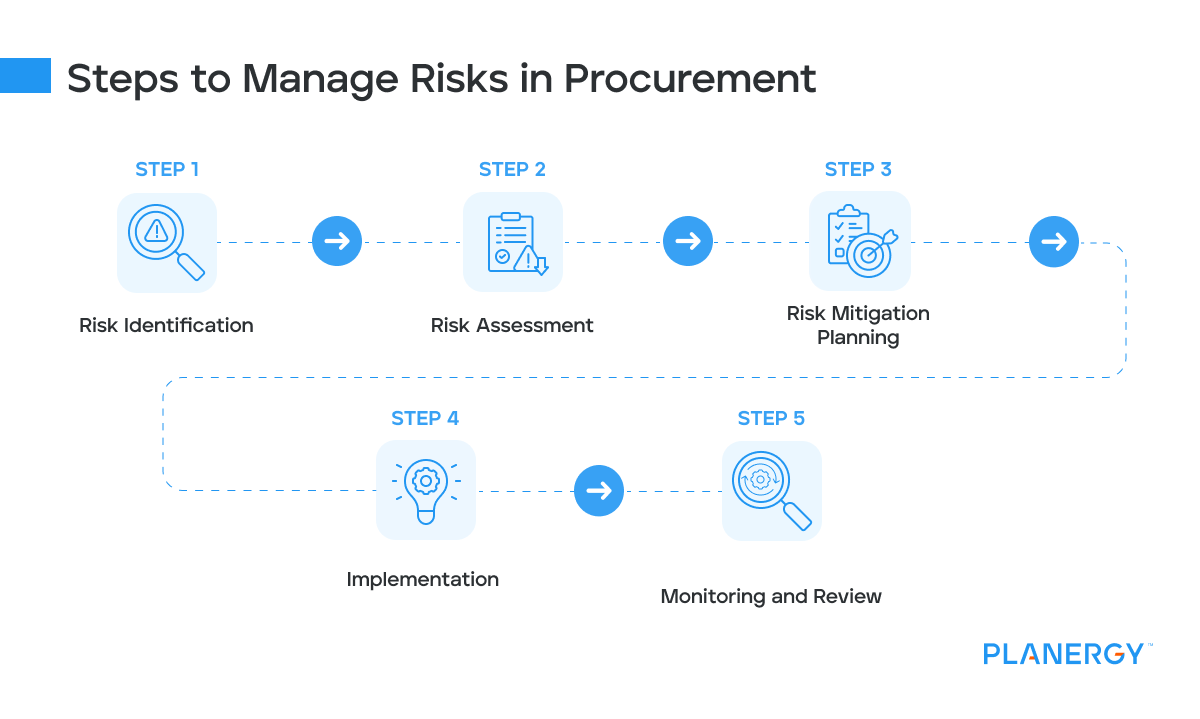

Steps to Manage Risks in Procurement

Risk Identification

Conduct thorough assessments to identify potential risks in the procurement process.

This involves mapping the entire procurement cycle and pinpointing areas where risks are likely.

Tools like SWOT analysis (Strengths, Weaknesses, Opportunities, Threats) can be useful.

The goal is to understand the potential risks associated with any given task, process, or supplier.

Typically, you can find risks coming from one (or more) of these sources:

- Strategic/Process-Driven Risk

- Project-Specific Risk

- Compliance Risk

- Quality Risk

- Logistical Risk

- Cost Risk

- Fraud Risk

As you identify potential risks, it’s a good idea to document them in a risk register.

This project management tool lets you identify risks and record their impact, frequency, and optimal resolutions as you move through the risk management process.

Risk Assessment

Evaluate the likelihood and impact of identified risks.

Prioritize risks based on their potential effect on the organization.

Risk assessment matrices and quantitative methods such as probability-impact assessments can provide clarity.

Using a risk assessment matrix, you can chart the overlap between the likelihood of risk and its potential impact.

Often referred to as a 5 x 5, it provides a visual reference useful in identifying the risks that need immediate correction.

You can assign each level a value and score a given procurement process, vendor, or other risk accordingly.

Probability of Occurrence Severity of Impact Negligible Marginal Major Critical Catastrophic Frequent 5 10 15 20 25 Probable 4 8 12 16 20 Occasional 3 6 9 12 15 Remote 2 4 6 8 10 Improbable 1 2 3 4 5 As you can see, costly or dangerous risks that occur frequently can be catastrophic and, therefore, need immediate attention, while unlikely events with little or even no impact on your company’s health, profitability, or reputation can be handled in a more leisurely fashion.

Risk Mitigation Planning

Develop strategies to mitigate identified risks, such as diversifying suppliers or implementing strict quality controls.

This could involve creating contingency plans, negotiating flexible contracts, and investing in technology to enhance visibility and control.

How you address each risk depends on its severity. Each situation may require a different combination of these control approaches.

Tolerance: Ideally, you wouldn’t have to tolerate any risk, but for low-risk items, the cost of removing them may exceed any gain from dealing with them.

All risks must be constantly monitored, reduced, or eliminated when it is cost-effective and reasonable to do so to avoid escalation.

Treatment: Any action taken to remove the risk or reduce its threat to a safe, tolerable level.

Most risks require this level of attention.

Transfer: With this approach, you transfer the risk to a third party better suited to handle it.

For instance, it may be better to outsource your IT and security to a specialized firm than it would be to hire in-house.

But, you must be sure you’ve accounted for the costs and additional impacts of shifting responsibility to someone else.

In some cases, a more direct approach (working with a vendor to bring them into compliance) can generate value and intangibles you wouldn’t get by pulling the plug or transferring to a third party.

Transformation: When risk reaches critical or even catastrophic levels, it might be time to step back and develop an entirely different solution.

Rolling with the punches is fine, but stepping out of the ring and finding a new strategy can help you win the day if disaster looms.

Implementation

Put the mitigation plans into action and ensure all stakeholders know their roles.

Clear communication and training are essential to ensure everyone understands their responsibilities and the steps to take if a risk materializes.

Monitoring and Review

Monitor the procurement process continuously for new risks and review the effectiveness of mitigation strategies.

Use key performance indicators (KPIs) and regular audits to track progress and adjust as needed.

Using the risk register you created when identifying risks, ensure every risk has a complete entry containing the following relevant information:

- Risk ID number or code

- Detailed description of the risk

- List of parties responsible for monitoring and controlling the risk

- Risk analysis data, including probability, impact, and date of analysis

- Actions taken, including any ongoing actions necessary to remove or control the risk

- Scheduled review date

As you monitor your procurement risks, update the risk register at each stage and review ownership roles regularly to ensure each risk is handled with maximum efficiency and efficacy.

The Different Types of Procurement Risks

Strategic Risks

Long-term risks affecting the overall procurement strategy, such as market changes and geopolitical events, require a strategic approach, including market analysis, scenario planning, and stakeholder engagement.

Operational Risks

Day-to-day risks, including supplier reliability and logistical issues.

Operational risks are often managed through robust processes, regular monitoring, and efficient resource allocation.

Compliance Risks

Risks related to adhering to laws, regulations, and internal policies.

Staying compliant requires continuous education, frequent audits, and proactive adjustments to policies and procedures.

Financial Risks

Financial risks are associated with cost fluctuations, currency exchange rates, and supplier financial stability.

Financial risks can be managed through budgeting, financial forecasting, and developing financial contingency plans.

Reputational Risks

Risks impacting the organization’s reputation due to poor procurement practices or supplier issues.

Maintaining a good reputation involves ethical procurement, transparent communication, and swift resolution of negative incidents.

Procurement Risk Management Strategies

Supply Chain Risk Management: Supplier Diversification

Source from multiple vendors to reduce dependence on a single supplier. This strategy spreads risk and increases the chances of continuous supply even if one supplier fails.

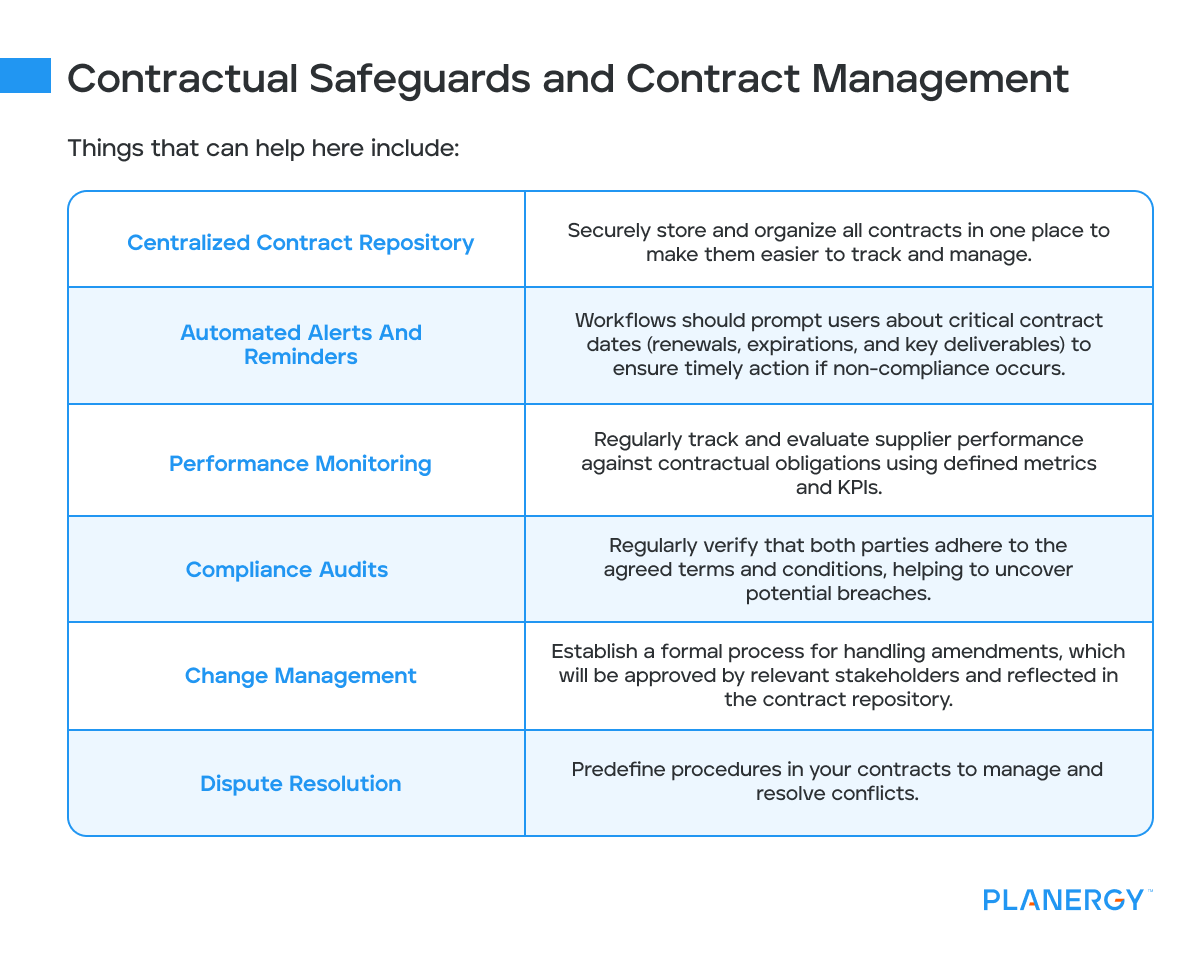

Contractual Safeguards and Contract Management

Including clauses in contracts to protect against price fluctuations, delivery delays, and quality issues.

Clear and detailed contract terms can prevent misunderstandings and provide legal protection.

Effective contractual safeguards go beyond the initial drafting of agreements.

You also need a solid contract management process to enforce and comply with all the terms throughout the contract lifecycle.

Things that can help here include:

Centralized Contract Repository: Securely store and organize all contracts in one place to make them easier to track and manage.

Automated Alerts and Reminders: Workflows should prompt users about critical contract dates (renewals, expirations, and key deliverables) to ensure timely action if non-compliance occurs.

Performance Monitoring: Regularly track and evaluate supplier performance against contractual obligations using defined metrics and KPIs.

Compliance Audits: Regularly verify that both parties adhere to the agreed terms and conditions, helping to uncover potential breaches.

Change Management: Establish a formal process for handling amendments, which will be approved by relevant stakeholders and reflected in the contract repository.

Dispute Resolution: Predefine procedures in your contracts to manage and resolve conflicts.

Supplier Audits

Audit suppliers regularly to ensure compliance with standards and reliability.

Audits help identify potential issues early and ensure that suppliers can meet your requirements.

Technology Integration

Using procurement software to automate and streamline the procurement process with controlled purchase order approval, enhancing transparency and control.

Automation technology can provide many benefits, such as real-time data, improving decision-making, and reducing human error.

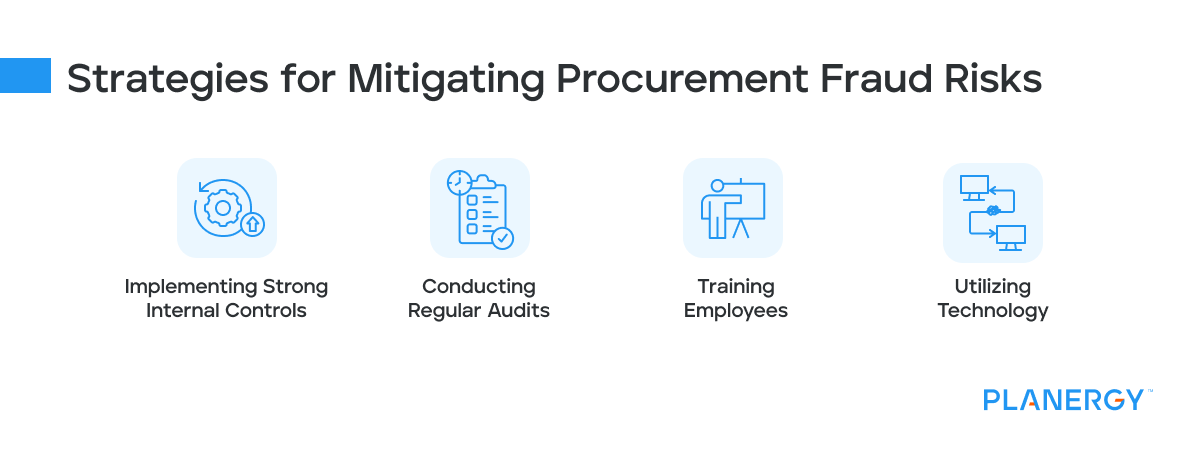

Strategies for Mitigating Procurement Fraud Risks

Implementing Strong Internal Controls

Establish clear policies and procedures for the procurement process.

Internal controls should include checks and balances, segregation of duties, and secure approval processes.

Conducting Regular Audits

Perform frequent audits to detect and prevent fraudulent activities.

Audits should be thorough and unbiased, focusing on financial transactions and operational practices.

Training Employees

Educate procurement professionals on recognizing and reporting fraudulent behavior.

Training programs should highlight red flags, encourage whistleblowing, and promote a culture of integrity.

Utilizing Technology

Adopt fraud detection tools to identify unusual procurement patterns and eliminate manual processes where possible.

Advanced analytics and machine learning can help detect anomalies and potential fraud early.

Strategies for Mitigating Financial Risk in Procurement

Hedging

Hedging strategies use financial instruments to protect against price volatility.

These strategies can involve futures contracts, options, and other derivatives to lock in prices and reduce uncertainty.

Negotiating Fixed-Price Contracts

Locking in prices to avoid future cost increases.

Long-term fixed-price contracts with suppliers can provide budget stability and reduce exposure to market fluctuations.

Supplier Financial Health Checks

Assessing suppliers’ financial stability regularly to prevent disruptions.

Financial health checks involve reviewing financial statements, credit ratings, and market performance to ensure suppliers’ financial soundness.

How Predictive Spend Risk Analysis Can Help with Procurement Risk Management

Predictive spend risk analysis leverages data analytics to forecast potential risks and trends in procurement spending.

By analyzing historical data and market trends, organizations can:

Identify Emerging Risks

Spot potential issues before they become critical.

Predictive analytics can highlight patterns and anomalies that indicate emerging risks, allowing for proactive management.

Optimize Spending

Make informed decisions on procurement strategies to minimize costs.

Data-driven insights can help identify cost-saving opportunities and optimize supplier negotiations.

Enhance Supplier Selection

Choose suppliers based on risk profiles and performance metrics.

Predictive analytics can provide a comprehensive view of supplier capabilities, past performance, and potential risks, aiding in better supplier selection.

Track and Tame Your Procurement Risk

Effective procurement risk management is essential for maintaining a resilient and efficient supply chain.

Organizations can ensure operational continuity, cost control, and quality assurance by understanding and mitigating various procurement risks, ultimately contributing to their long-term success.