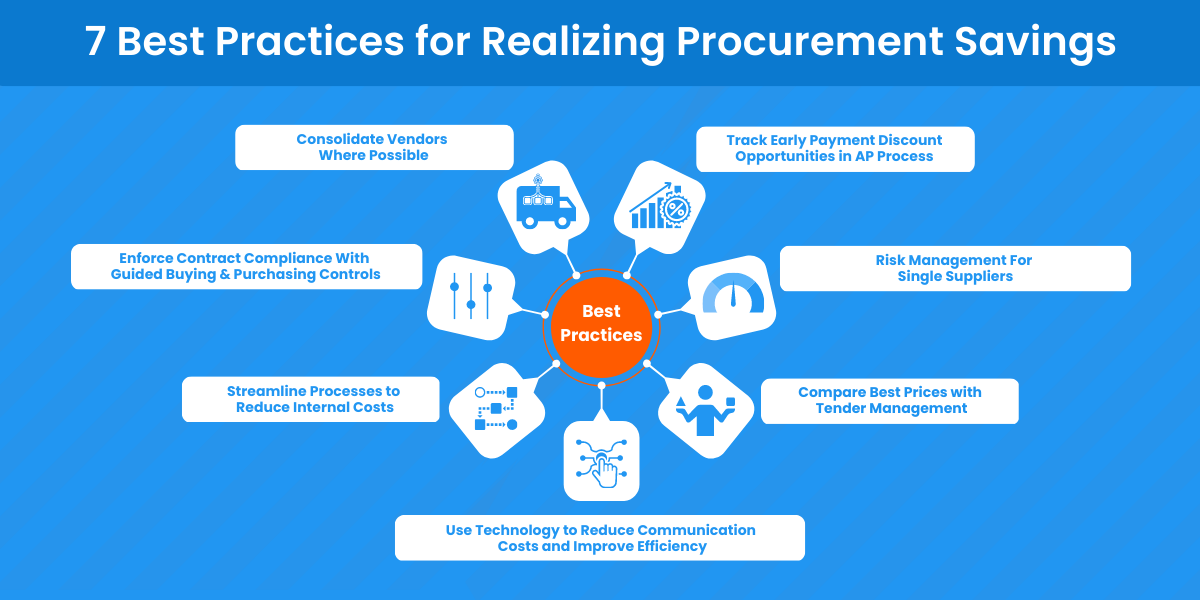

Following best practices can help procurement professionals to maximize realized savings from identified savings opportunities.

There are many best practices to follow, all of which are easier to implement with procurement software as opposed to manual methods. These best practices include the following seven strategies and tips.

Consolidate Vendors Where Possible

Supplier relationship management is critical to maximizing procurement savings. By consolidating the total number of vendors you work with, you can save time and money.

Consolidation often means you can get volume discounts and higher quality goods or services, and because there are fewer suppliers to manage overall, the process becomes more efficient.

Consolidating vendors can also help with cost avoidance. By focusing on ways to reduce the rate of cost increases or negotiating contracts with value-added services—such as extended warranties or free shipping—you avoid future costs and create procurement savings.

Track Early Payment Discount Opportunities in the AP Process

No vendor likes waiting 30 days more to receive payment, and many will offer discounts in exchange for early payment. Set up a system to track opportunities for early payment discounts—ideally in your e-procurement system—to increase cash flow.

Once your system has those opportunities identified, you can streamline the payment process to maximize these discounts.

You’ll need to ensure that your invoice processing system (which can be part of your procure-to-pay software system) is agile and able to fast-track approvals and payments when necessary.

Slow and manual payment systems will cause you to miss out on these opportunities.

Enforce Contract Compliance With Guided Buying and Purchasing Controls

Maverick spend, also known as spend leakage and rouge spend, is when employees make purchases outside of negotiated contracts and preferred suppliers.

This often disregards procurement organization goals and best practices and is made to satisfy immediate needs with no regard for cost, quality, or savings.

Maverick spend can decimate procurement savings, but procurement teams can take action by making it easier to purchase in the right way with a guided buying system.

This system is a catalog of preferred suppliers with contracts in place that teams can choose from to make the purchases they need.

Another way to avoid this cost is to enforce internal purchasing controls. These controls are a set rules for purchasing that include approvals, spending limits, preferred vendor restrictions, and more.

Using an e-procurement system can help you automatically enforce these controls and make it next to impossible for maverick spend to occur.

Supplier Risk Management

One of the biggest risks companies face is supplier dependence. While you should aim to consolidate suppliers and vendors when possible, one of the key ways to manage risk is to ensure procurement doesn’t depend too much on any single supplier.

Procurement teams can mitigate this risk by always having a backup supplier available to cover the most important goods and services required to keep operations running smoothly.

Streamline Processes to Reduce Internal Costs

By streamlining processes, you can reduce operational costs. Procurement should work with other departments to define transparent processes. With improved visibility into overall spending and data accuracy, it’s easier to reduce transaction costs and failure costs.

Using e-procurement software is one of the easiest and fastest ways to define processes, collaborate with other departments, and reduce internal procurement costs over the long haul.

Compare Best Prices with Tender Management

Tender management is the process of soliciting bids, or tenders, that include competitive pricing, usually done through an RFP or RFQ.

When you provide numerous companies with the opportunity to bid for the work, their bid should include how their company will solve your business problem and provide a competitive price for the work.

Using tenders you can see baseline costs and set benchmarks for what you should be spending. It will help find you the best and most cost-efficient options for getting the supplies you need and help you make the right choice.

Use Technology to Reduce Communication Costs and Improve Efficiency

Use e-procurement software and other technology so you can communicate faster and more efficiently with your procurement department and suppliers.

You’ll have improved access to supplier catalogs, giving you a better range of product choices that could lead to increased savings.

Good procurement function management is necessary to ensure your company remains profitable.

Keeping an eye on procurement savings opportunities and actively reducing costs gives you more freedom in your budget to invest in other ways to help your company grow.

To realize your procurement savings goals, using the right tools matters. PLANERGY can help you hit your savings target and reduce inefficiencies throughout your procurement process.