Why Do Supplier Tiers Matter?

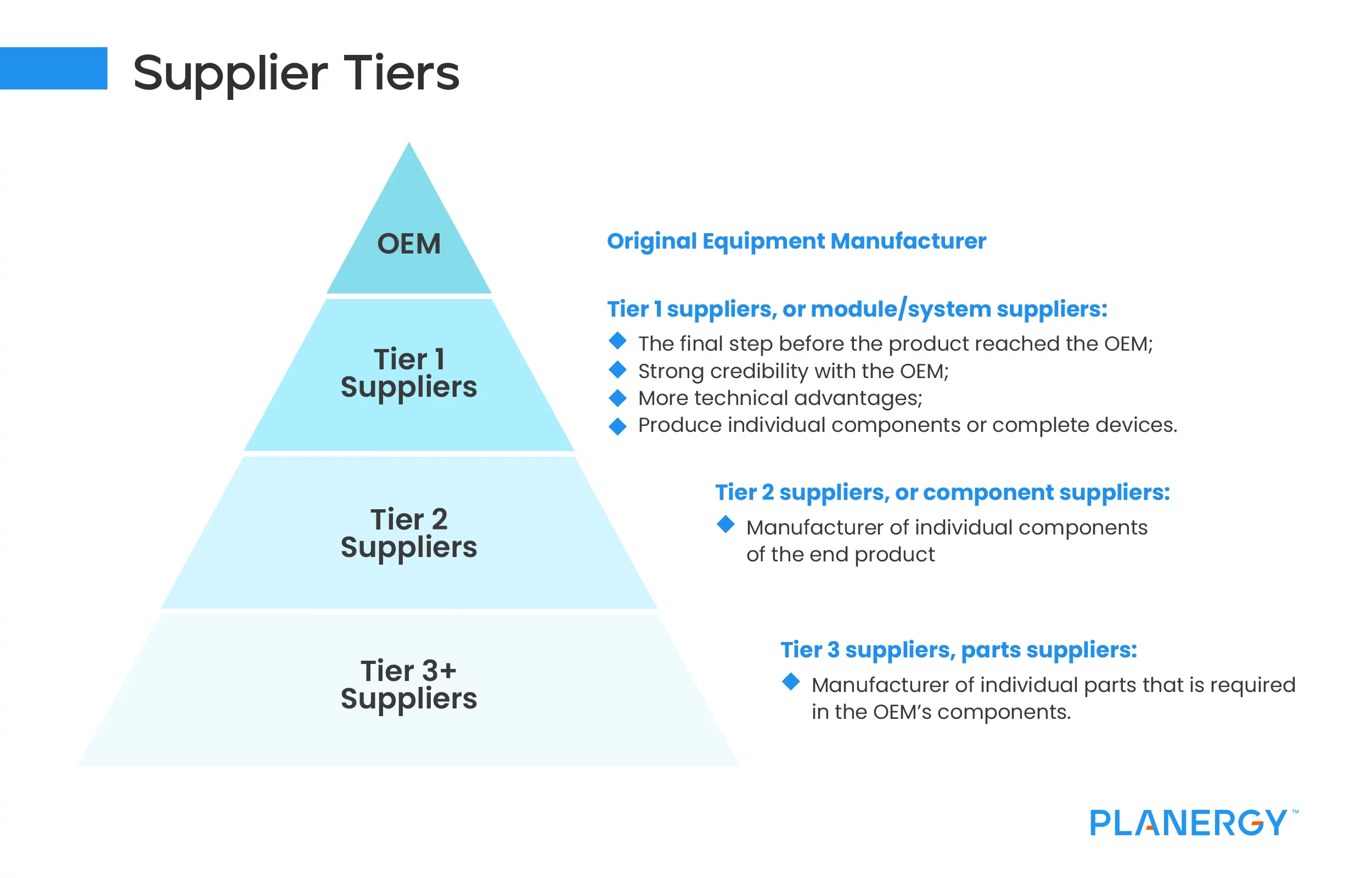

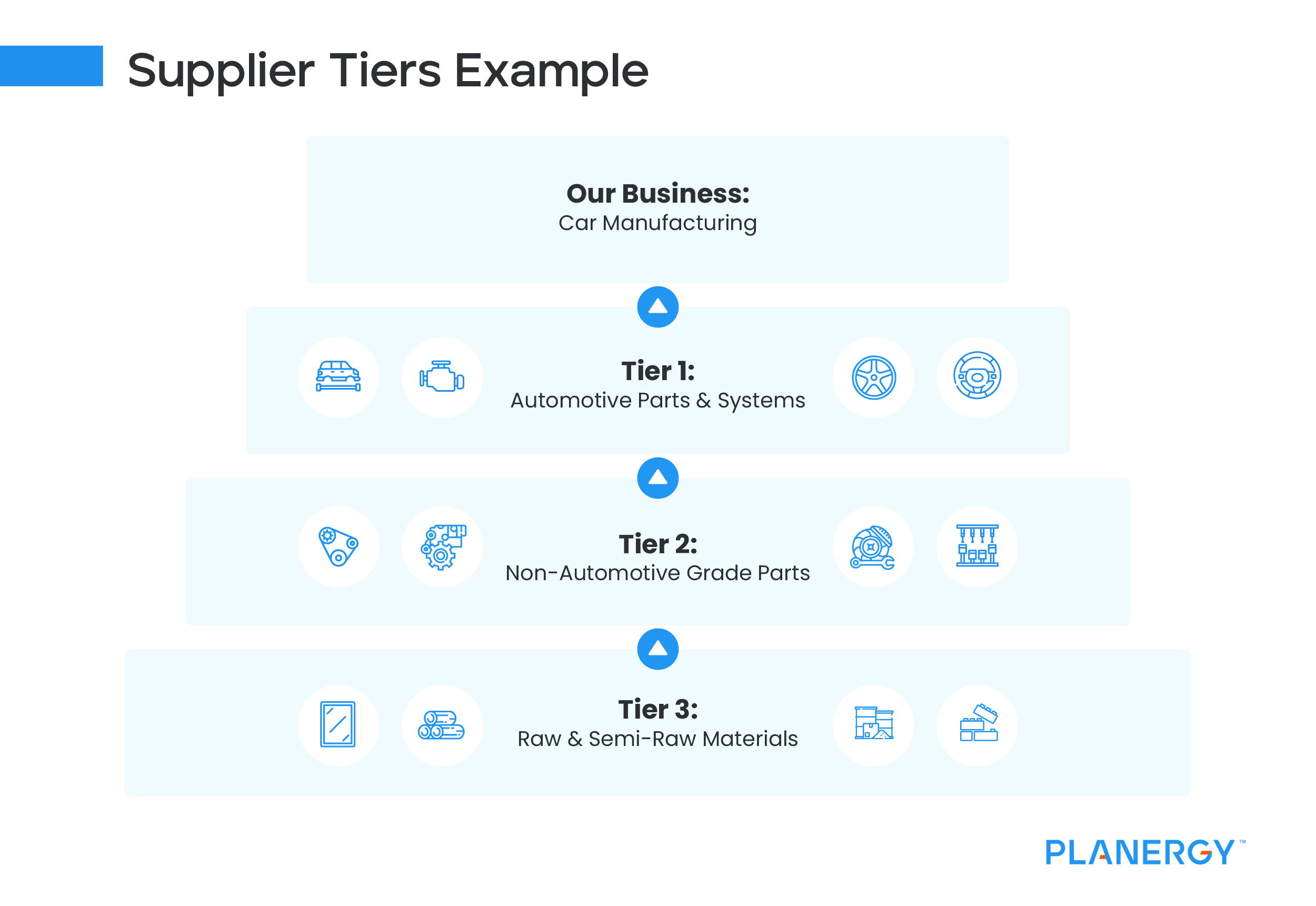

The main reason why supplier tiers matter is because it helps you prioritize which suppliers should be managed first.

For example, if you have limited resources available for managing your supply chain, then it makes sense to focus on your tier 1 suppliers since they’re providing products and services that are critical to your operations.

It also helps when deciding which products or services to outsource—you may outsource a product from a lower-tier supplier simply because it’s not as important as something supplied by a first-tier supplier.

Why It’s Important to Know Your Different Suppliers

Companies need to know who their suppliers are and what services they provide. Knowing your suppliers can have far-reaching implications for a business, from quality control to legal ramifications and ethical concerns.

First and foremost, knowing your suppliers helps to ensure product quality. If you’re working with multiple faraway vendors, it isn’t easy to maintain control over the materials being used or processes that take place in manufacturing.

Quality assurance is especially important when it comes to food safety.

Ensuring that all ingredients are sourced from reputable suppliers is vital for maintaining a product’s health and safety standards.

Another key consideration is how ethical a supplier’s practices are, especially because today’s consumers are focused on social responsibility.

Does the supplier employ fair labor practices? Are there any cases of human trafficking or other unethical activities associated with them?

Companies should aim to form relationships with suppliers that uphold ethical standards and regulations to avoid becoming complicit in any wrongdoing by association.

Legal issues can also arise when dealing with suppliers if they fail to comply with relevant labor laws or other regulations related to their business operations.

Companies need to have an understanding of their liabilities regarding third-party contractors so as not to be held responsible for any infractions on their part.

Considering environmental sustainability is another factor when vetting potential vendors.

Companies need to determine how much energy suppliers use, whether they produce waste responsibly, and whether they commit resources toward reducing emissions or developing renewable energy sources like solar power or wind energy generation.

Additionally, businesses should look into a prospective supplier’s ESG Index score, which measures its ESG performance across different industries—an important metric when selecting partners who subscribe to sustainable practices and values.

Cybersecurity is another point worth mentioning here: no matter how secure your internal systems may be, if you’re working with an insecure third-party vendor, you could still be at risk for data breaches that could damage your reputation or lead to financial losses due to stolen information or ransomware attacks.

Suppliers must have robust security protocols that meet industry standards for companies to feel safe working with them digitally.

Understanding who you work with as a company is essential for ensuring compliance with legal regulations, maintaining ethical standards, protecting against cyber threats, and contributing toward more sustainable business operations—all while maintaining high-quality products and services according to customers’ expectations.

To ensure these aspects are taken care of properly, businesses need knowledge of their supplier networks to properly vet potential partners before engaging in any contracts or agreements.