Efficient supply chains play a major role in keeping schools running smoothly. When everything runs as expected, students have the materials, technology, and meals they need to succeed.

But what happens if those supply chains are disrupted?

Understanding how school supply chains work and their challenges is critical to finding ways to keep educational services uninterrupted.

What Does a School Supply Chain Look Like?

A supply chain is the network that ensures the necessary goods and services reach classrooms, cafeterias, and administrative offices.

This process involves multiple moving parts.

Procurement

Items like textbooks, computers, cleaning supplies, and food come from vendors.

The school’s procurement team ensures schools can order the necessary items while maintaining the budget and standards.

Delivery and Logistics

Transportation is a key component, since goods must be distributed to the right locations, whether it’s individual schools in a district or specific facilities.

Storage and Inventory Management

Specific resources, like office supplies and food, require storage for future use.

Schools must balance having enough inventory to avoid shortages and not having so much that it leads to waste.

End-Use and Oversight

At this point, the goods arrive at their final destination (classrooms or kitchens, for instance) and complete the supply cycle.

Accurately tracking and managing the resources ensures that everything is used efficiently.

Common Causes of Supply Chain Problems

School supply chains may be more vulnerable than other industries because they work within limited budgets, often relying on seasonal purchasing to make the most of their available money.

Disruptions could come from several angles, and when it comes to education, these supply chains are more fragile than others.

Economic Instability

Fluctuations in material prices (paper, fuel, etc.) directly impact procurement budgets.

Consider this: the average school bus gets 6 to 10 miles per gallon.

According to the North Carolina School Bus Safety website, the average annual fuel use per school bus is 1,913 gallons.

At North Carolina’s average price of $2.764 per gallon, that translates to $5,287.53 per bus per year.

When you consider the number of buses required to service students, even a minor increase in fuel prices can make a huge impact on the overall budget.

Sure, schools can leverage volume to secure discounts the general public won’t be able to secure, but even a deviation of a few cents per gallon at that scale is potentially detrimental.

Fuel cost increases can also drive up the cost of delivering supplies to districts.

Considering public school budgets for each school year are approved months, sometimes years in advance, a sudden change in pricing can wreak havoc.

School nutrition programs are required to follow certain guidelines (in the United States, that’s the U.S. Department of Agriculture or USDA) to ensure students get healthy meals.

If there’s an issue with food costs, it may mean changing menu items, but it’s not as simple as going to the local grocery stores to get the substitutions and seeking reimbursement.

Vendor Delays

Delivery issues can also arise from multiple sources.

From labor strikes and transportation to poor vendor management, if you don’t get the items you need on time, it slows everything else down and could turn a minor issue into a major one.

If the main vendor for your school meals isn’t able to supply the required ingredients for your meal program, you still have to provide something for the children to eat.

What will you do for your school food service? If there’s not time for your food service director to find a new distributor, will you be able to affordably source local food?

Picture this: Your school district is waiting for interactive whiteboards at the start of a new semester.

If the vendor experiences a delay, teachers have to use less engaging teaching methods.

The delays cause frustration and reduce the effectiveness of the educational experience.

Long lead times may be less disruptive in other sectors (especially when they can be planned around), but schools are required to stick to strict academic calendars that leave little room for flexibility.

Natural Disasters

Weather events like floods, wildfires or hurricanes don’t just damage distribution infrastructure; they also can destroy inventory storage and make transportation more difficult.

Schools in disaster-prone areas often deal with repeated disruptions that can greatly disrupt the supply chain.

For instance, school districts hit by hurricanes may lose food inventory stored in a flooded warehouse.

Businesses elsewhere may be able to procure additional supplies from other locations quickly, but schools are often stuck waiting for funding, approval, and logistics, which slows recovery even further.

A prime example is the schools in the mountains of Western North Carolina after Hurricane Helene.

The widespread lack of power and internet meant that in-person learning was the only option.

The City of Asheville also suffered massive water infrastructure damage, leaving the residents without water for nearly two months.

At one point, schools in the City of Asheville considered drilling individual wells at each school in the district to get students back to class faster.

When drilling wells is faster than waiting on other solutions, there’s a big problem.

District leaders ended up seeking waivers to change the school schedule.

Restaurants could restore service much faster by hauling water tanks from other sources, which wasn’t an option for the education system.

Supply Scarcity

Global shortages or limited access to specific materials can halt school operations, especially for niche or seasonal supply needs.

The COVID-19 pandemic provided stark examples of schools struggling to acquire personal protective equipment (PPE) such as masks, hand sanitizers, and cleaning products.

Scarcity in more routine supplies like Chromebooks for e-learning forced many schools to pause digital learning programs.

Unlike corporate buyers who prioritize their purchasing power, schools often lose out during periods of high demand, leading to more disruption than in other industries.

Technological Failures

Many schools operate with outdated procurement and inventory management systems, which are more error-prone.

Issues arise from poor cross-departmental communication, or failures in legacy software not designed to address modern logistical challenges.

Consider this: If a school district adds incorrect order quantities to its system, this leads to either overstocking or understocking.

Extra items may lead to budgetary waste, but shortages of basic supplies could create operational chaos.

A poor technological infrastructure limits a school’s ability to adapt during crises, leaving it less competitive when faced with errors or delays.

The Ripple Effect on School Operations

Supply chain disruptions create a domino effect in schools, impacting students, teachers, and administration.

Because of the rigid operational schedules and budget constraints, supply chain issues reverberate more than in other sectors.

Operational Inefficiency

Delays in receiving textbooks or educational technology hamper lesson plans, affecting student learning outcomes.

Budget Overruns

Schools may face higher costs when purchasing goods during delays or emergencies.

Since the money has to come from somewhere, this often means pulling funds from other priority areas, creating a potential mess for your accounts payable department.

Even GAG pooling within multi-academy trusts (MATs) may not stop the issue.

Decline in Student and Staff Productivity

Staff spends more time managing crises or finding alternate sources of supplies than focusing on education and operations.

When the staff focus shifts, student outcomes do, too.

And when the staff isn’t happy, it may lead to a mass exodus, creating labor shortages.

Erosion of Trust

Parents and communities lose faith in schools’ ability to provide essential services if disruptions are frequent.

Parents expect schools to provide a safe and consistent learning environment.

An ongoing shortage of materials or repeated delays in fulfilling basic needs—like providing school lunches or maintaining clean facilities—can lead to frustration, complaints, and even reduced community support for school programs.

Moving money to account for budgetary changes may mean stopping other initiatives, which may negatively affect your district for months or years to come.

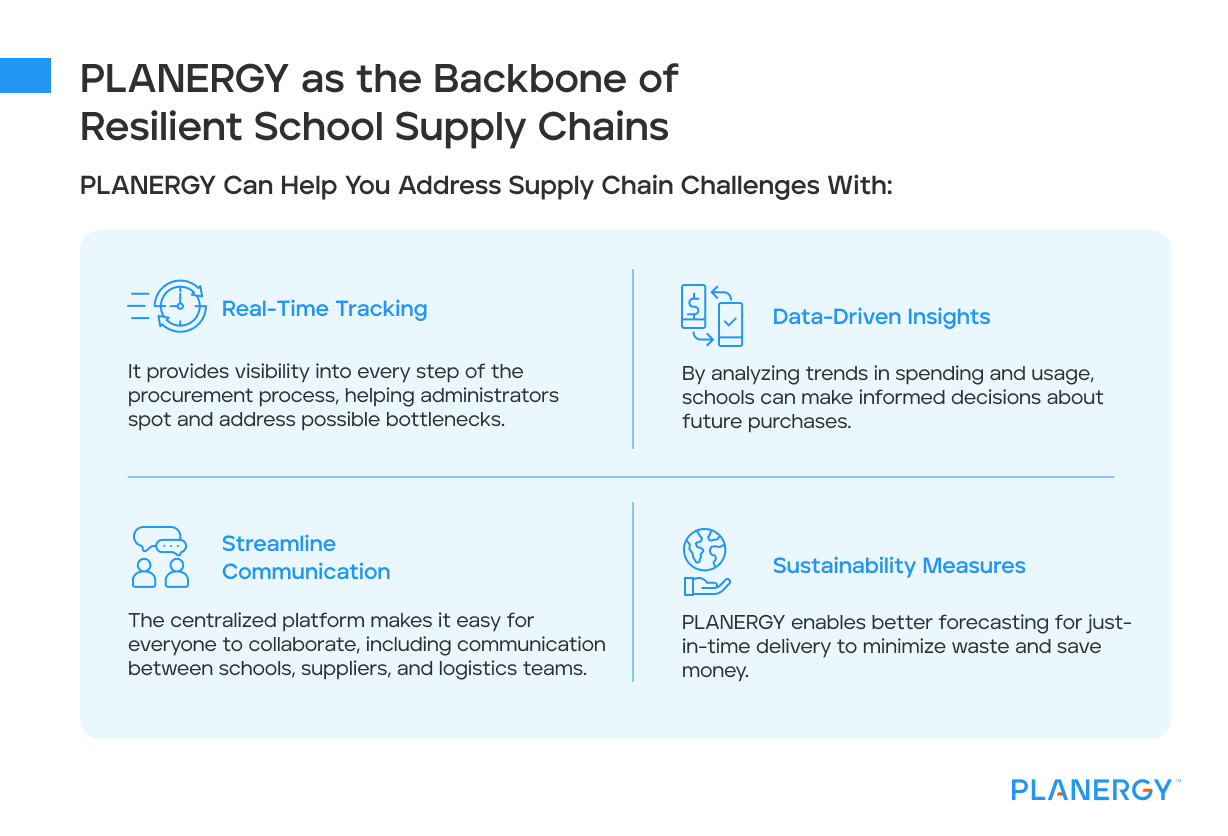

PLANERGY as the Backbone of Resilient School Supply Chains

Integrating technology into supply chain management is no longer optional, it’s required.

PLANERGY, a cloud-based procurement and spend management software gives schools the tools to withstand disruptions and thrive.

PLANERGY can help you address supply chain challenges with:

Real-Time Tracking

It provides visibility into every step of the procurement process, helping administrators spot and address possible bottlenecks.

Data-Driven Insights

By analyzing trends in spending and usage, schools can make informed decisions about future purchases.

Streamline Communication

The centralized platform makes it easy for everyone to collaborate, including communication between schools, suppliers, and logistics teams.

Sustainability Measures

PLANERGY enables better forecasting for just-in-time delivery to minimize waste and save money.

Strategies to Minimize Supply Chain Risks

While you won’t be able to fully eliminate supply chain risks, there are things you can do to minimize them.

Diversify Your Supplier Base

Working with multiple suppliers reduces dependence on any single vendor and protects against disruptions.

Leverage Forecasting Tools

Technology like PLANERGY can gather usage data to predict demand accurately, helping schools prepare for peak purchasing periods.

Enhance Inventory Management

Build a buffer stock of your most essential goods, such as paper, ink, and technology components (laptop chargers, extra laptops, etc.), to absorb shocks without hindering services.

Train Staff

Equip employees with the skills and knowledge to effectively manage procurement and inventory tools.

This way, you can maintain smoother operations during crises.

Set Contingency Plans

Always have a Plan B (and maybe even C and D) to deal with disruptions, such as pre-negotiated contracts with alternate suppliers.

Best Practices for Inventory Management During Disruptions

Even with advanced planning and preparation, schools should follow certain practices to manage inventory in a crisis.

Prioritize Essentials

Focus efforts on securing high-priority items like food supplies and teaching materials.

Regular Audits

Regularly review inventory levels to find waste and avoid shortages.

Maximize Storage Efficiency

Use organized storage systems so you can quickly access resources in urgent situations.

The Power of Supplier Relationships

Strong communication and trust with suppliers can prevent many supply chain headaches. Build partnerships by:

- Establishing long-term agreements for consistent supply.

- Sharing detailed forecasts to help suppliers prepare production cycles.

- Recognizing reliable vendors with loyalty programs or preferred status.

Looking Ahead: Emerging Trends in Supply Chains

School supply chains demand innovation and adaptability.

Trends we can expect to see in the future include:

- Sustainable Procurement: More schools will turn to eco-friendly and cost-efficient solutions.

- Automation Expansion: Increased reliance on AI and machine learning for managing supply chains.

- Resilient Infrastructure Development: Schools will design supply chains with built-in contingency measures to combat future disruptions.

Flexibility, preparedness, and an openness to leveraging cutting-edge technology will define the success of school supply chains in the coming years.

With tools like PLANERGY leading the way, educational institutions are better equipped to handle the challenges and continue delivering exceptional services, even in uncertain times.

By fostering strong supplier relationships, using data intelligently, and sticking to robust inventory practices, schools can ensure that no disruption blocks their mission of educating future generations.