Before the advent of mass production, few could imagine a world where everyday goods were cheap, plentiful, and available in every market across the globe.

The same could be said for the average person working in the candlelit world before electricity and assembly lines, or the punch-card-and-paper-pushing denizens of the pre-digital era.

Technology has a way of creating shockwaves of disruptive transformation in our society, and in the early decades of the twenty-first century, we find ourselves at the edge of a fourth industrial revolution, poised to change our understanding of how we conduct our business—and our lives—forever.

New technologies, packed with both the potential for powerful positive change and a few corresponding potential perils for the underprepared, are already transforming commerce, entertainment, and existence itself.

By exploring the history of technological change, and how our societies have adapted in the wake of disruptive transformation, you can better prepare your company to thrive in the world of the fourth industrial revolution.

The Fourth Industrial Revolution: An Overview

Before you can assess the potential impact of the fourth industrial revolution (also called Industry 4.0) on your life and business, it’s critical to understand how we got here.

The foundations for today’s digital technologies like quantum computing and machine learning were laid in previous industrial revolutions.

The First Industrial Revolution (Late 18th Century/Early 19th Century)

The original Industrial Revolution introduced the concepts of standardization, basic process optimization, and mass production to a world where goods were usually made by hand, using methods that might vary from valley to valley or even craftsperson to craftsperson in the same village.

Animal power and steam engines created the capacity to produce at levels unimaginable using human labor alone, and mass production became the new standard operating procedure for producing everyday goods.

The Second Industrial Revolution (Late 19th Century/Early 20th Century)

Steel and electricity were the parents that gave birth to the Second Industrial Revolution.

Better materials, more effective mechanization, and greater production power from improved energy sources, combined with refinements in efficiency, were the perfect environment for technological innovations like automobiles and trains to thrive.

As markets and supply chains expanded to global proportions, meeting growing demand was made possible by the introduction of the assembly line, created and perfected by canny engineers on the payroll of automobile tycoon Henry Ford.

The Third Industrial Revolution (Mid-20th Century)

In the 1950s, analog and mechanical technologies gained extra power from the addition of computerization to the production process.

Software transformed the way in which “the business of doing business” was conducted, and laid the groundwork for future technologies that would seek to remove human error and tedium from repetitive and predictable tasks.

During the third industrial revolution, humans began to recontextualize ourselves, reserving more and more creative, administrative, and strategic tasks that required a human touch for ourselves, and shifting the “drudgery” to the tech tools we’d invented to ease the load.

The Fourth Industrial Revolution, AKA Industry 4.0 (Late 20th Century-21st Century)

They say hindsight is 20/20, and looking back, it’s easy to draw a line from mass production to enhanced energy sources to important conceptual shifts in process efficiency to see how we built the world we currently live in, even though today’s world was as unimaginable to an 18th-century craftsperson as the life of a 23rd century workers is to us today.

That said, we can look at the digital technologies that define the Fourth Industrial Revolution and understand the potential they have to transform our lives in new and exciting ways.

If previous iterations were about transforming work through technology, Industry 4.0 is about blurring the lines between our digital and biological worlds.

Artificial intelligence (AI), especially as expressed by machine learning, can replicate and mimic human intelligence, supporting new technologies as diverse as autonomous vehicles, customer support chat bots, public-facing social media management applications, and virtual companions that grow more sophisticated and human-like as they learn.

Automation technology works hand-in-glove with AI to effectively remove humans from the most basic tasks, increasing security, accuracy, and efficiency while freeing team members to apply their human skills, intuition, and creativity to more valuable projects and processes.

Add in powerful data security and manipulation using the blockchain, and you’ve got the potential for a rock-solid, customizable, and constantly-evolving information environment where every process is built on continuous improvement, every automatable task is handled by machines, and human team members enjoy greater productivity, convenience, and morale while working toward organizational goals.

The combination of the real world with the digital realm, sometimes called cyber-physical systems, is already in heavy use via the Internet of Things (IoT), which can produce real-time duplicates for production testing and prototyping, or allow physical manipulation of real-world objects by digital users, whether they’re human or AI.

3D printing brings digital assets into the real world, simplifying production and prototyping and, in a somewhat ironic twist, bringing home production of mass-produced goods back into the limelight.

There is, after all, a certain undeniable similarity between the home potter of ages past, spinning up a vessel based on popular designs, and the person who downloads a file for a pot they fancy and prints it at home.

Virtual reality (VR) plays a similar role, allowing companies to explore new environments and work with new prototypes in cyberspace without the need for physical resources. At home, consumers can play games, experience virtual tourism, or even head into work without leaving their home office.

Connecting all of these technologies is the cloud, which has the simultaneous effects of decentralizing data storage and management while creating a single point of access for stakeholders, with greater security, versatility, and accessibility than could be imagined in the days of manual workflows and paper-based processes. In the near future, it’s possible quantum computing will

At its heart, the fourth industrial revolution is a digital revolution; one that’s:

- Cloud-based

- Mobile-friendly

- Disrupting both virtual and physical worlds

- Focused on interconnectivity, communication, and collaboration

- Driven by technologies that promote continuous improvement, systems thinking, and personalization.

The promise of the fourth industrial revolution is a world with unprecedented economic growth and quality of life for the world’s people, with intelligent tools that help us make smarter decisions about everything from business growth to better self-driving cars to repairing our damaged planet.

It’s not all rosy, however. Author, economist, and Executive Chairman of the World Economic Forum, Professor Klaus Schwab warned in his book The Fourth Industrial Revolution that the new era would also be fraught with the possibility of peril.

Without careful stewardship, increased inequality of income levels and social divides, exacerbated by “haves” and “have nots” in a world built on digital skills and toolsets, can crop up across the globe—particularly as labor is radically transformed by automation and artificial intelligence.

If previous iterations were about transforming work through technology, Industry 4.0 is about blurring the lines between our digital and biological worlds.

Preparing for the Fourth Industrial Revolution

Looking at the disruptive digital technologies transforming today’s business landscape, it might seem impossible to choose just one strategy that ensures your company is ready to handle both the best and the worst of what’s coming over the horizon.

That’s not necessarily the case, however. Two departments present in every business—procurement and accounting—have the potential to bring digital transformation into your workflows and help you build a foundation for Industry 4.0 across all your business units.

Investing in a complete, cloud-based procurement solution such as PLANERGY gives you plenty of options.

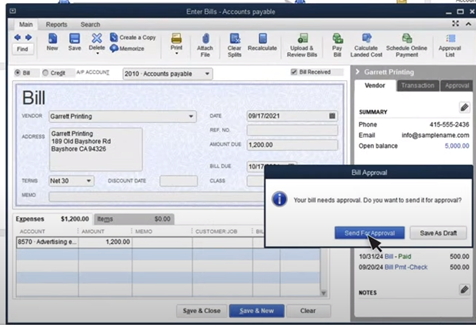

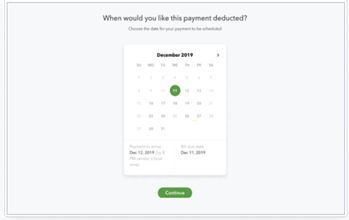

You can start small, automating your most critical processes for greater efficiency and cost savings.

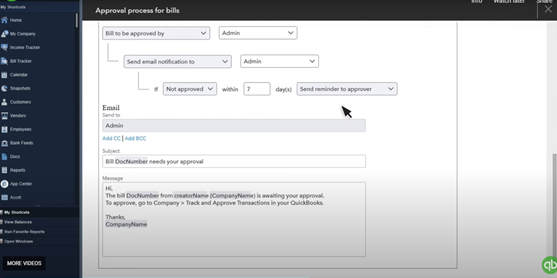

Or, you can embrace digital transformation more enthusiastically and streamline your entire procure-to-pay process, effectively freeing both your procurement team and your accounts payable staff from low-value, repetitive tasks while simultaneously introducing continuous improvement to crucial workflows.

Centralized data management, powerful data analytics, and improved communication and collaboration are just a few of the additional benefits that come with such an implementation.

Automating your processes reduces waste, increases efficiency and accuracy, and creates not just savings, but value by sparking a cultural transformation in your business.

Optimizing the P2P process creates a ripple effect; more discounts are captured; better supplier relationships are forged; rogue spend, invoice fraud, and inaccurate reports are eliminated.

Artificial intelligence, blockchain tech, and machine learning allow you to introduce smarter vendor portals, support from chat bots, and rock-solid data security into all of your spend-related processes.

And since spend touches every area of your business, the ripples spread even further as more and more stakeholders embrace these tools for their own approval workflows, report generation, financial and marketing forecasts, and product innovation initiatives.

In time, your human staff will be investing their time and talents where they’re needed most, supported by technology that gets the job done and provides rich data for strategic planning and decision making.

Is Your Company Revolution-Ready?

We live in a time of great promise, where tomorrow’s tech is already changing the way we live, work, and play today.

Researching and implementing automation, artificial intelligence, and other technological innovations as part of your business strategy will give your company the power, competitive strength, and versatility it needs to take advantage of wonders yet to come.