Purchase orders (POs) are powerful. They generate a lot of useful information as they go through your purchasing department, the vendor, and your accounting department.

However, if you’re not using a purchase order tracking system to connect that information, you’re missing out on insights, wasting time and money, and increasing risk.

Traditionally, companies have relied on Excel and paper-based manual processes to keep track of purchase orders, which is time-consuming, difficult, and impossible to monitor in real-time.

Thanks to new technology and proven purchase order processes, it’s now easy and affordable to create POs and track them across their entire lifecycle.

In this article, we’ll explore how to track POs and the benefits of automated PO tracking, but first, let’s start with the basics.

What Is a PO Number?

A PO or purchase order number is a unique reference number assigned to a PO that is used to track it throughout its lifecycle. This number is generated by the buyer and sent to the seller. Once it’s assigned it confirms that the buyer officially intends to make this purchase.

Once a PO number has been assigned by the buyer and the PO has been signed by the seller, the purchase order becomes a legally binding contract. That means that the seller can provide the goods or services named in the PO, send an invoice with the PO number references, and expect to be paid (with legal recourse if they’re not)

What Is the Lifecycle of a Purchase Order?

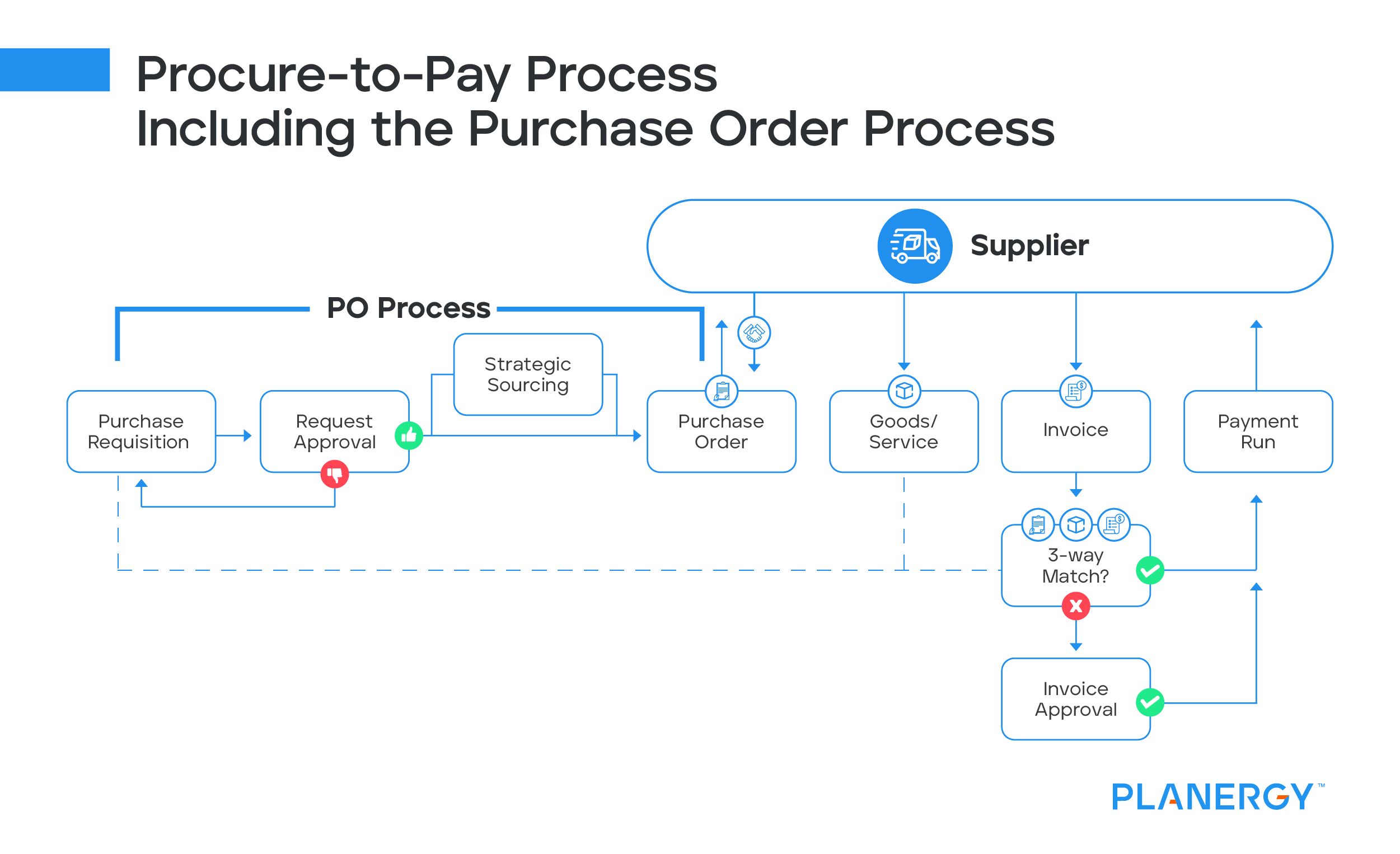

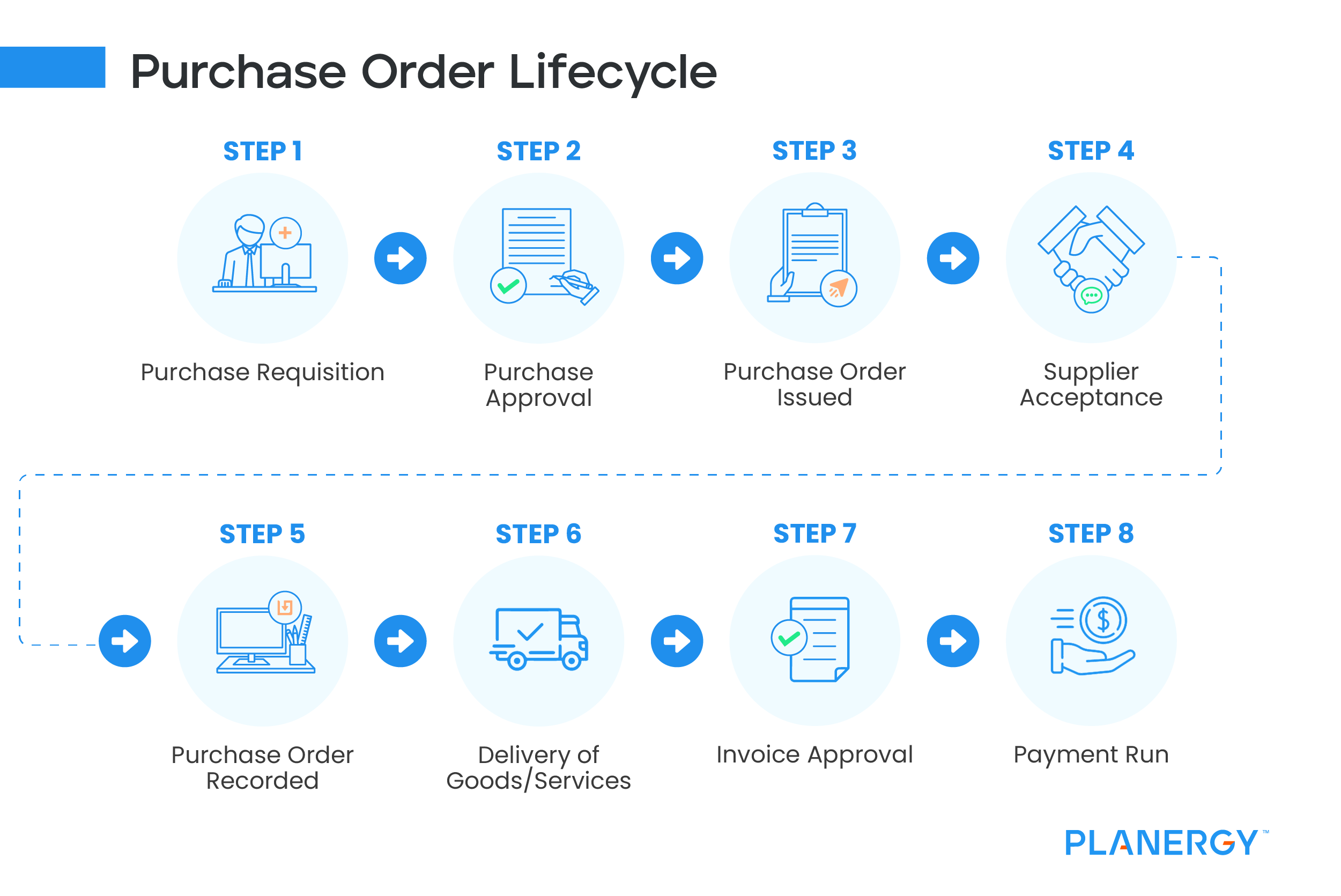

The purchase order life cycle, or purchase order process, is the set of key steps involved in processing a purchase order. The larger and more scrutiny a purchase undergoes, the more steps the PO lifecycle takes.

The PO lifecycle is part of a larger procurement process and is complete once the PO is officially recorded, which happens before an order is fulfilled and paid.

The typical purchase order lifecycle consists of the following steps:

Purchase Requisition

The purchaser creates a requisition that is sent to internal team members to review and approve or reject.

Purchase Approval

The purchase requisition gets approved and signed by the necessary approvers. Depending on internal policies, this can be done by one approver or multiple. It often depends on the value of the purchase.

In some cases, the request is routed through strategic sourcing if an existing preferred supplier is not in place, to ensure the best price.

Purchase Order Issued

Once approved, the purchaser issues a PO to the supplier with all the necessary information such as expected cost and total units and assigns a unique PO number.

Supplier Acceptance

The purchaser sends the PO to the supplier, who then approves, rejects, or sends the PO back for further discussion. If approved, the supplier will provide the goods and services and send an invoice for payment.

Purchase Order Recorded

Once the PO is signed by the supplier, the purchaser can officially record the PO and file it in their books.

When speaking of the lifecycle of a purchase order you can consider this to carry through all the way to payment, incorporating the full procure-to-pay process.

Delivery of Goods/Services

The supplier delivers the goods or services and the relevant receiving documents are recorded with line items verified against the PO to ensure that everything that was ordered is delivered.

Invoice Approval

When the invoice is received by accounts payable from the supplier it will need to be approved for payment. This process typically involves 3-way matching, which cross-references the invoice against the PO and the packing slip or order receipt to ensure the goods and services delivered match what was purchased.

Invoice processing and approval can be streamlined greatly by using AP Automation Software like PLANERGY.

Payment Run

Once successful 3-way matching is complete, the invoice will be included in the next payment run and the supplier will be paid in full. At that point, the PO will be marked as paid and the PO number can be used to reference and track the PO for financial reports.

What is Purchase Order Tracking?

Purchase order tracking means monitoring purchase orders throughout their lifecycle and beyond. Most commonly, it’s used as a method to monitor spend associated with POs from the purchase requisition to the final reconciliation and payment.

PO tracking can be as simple as a spreadsheet or as complex as enterprise Procure-to-Pay Software.

While PO tracking is generally about tracking spending, most PO tracking systems are created with common goals that go beyond just spend management:

- Standardization to cut processing times, workflow delays, and errors. Ideally, real-time monitoring helps prevent problems before they begin.

- Reducing payroll costs and minimizing resources consumed.

- Improved document management, inventory control, supplier management, and process optimization. Every PO number connects its corresponding purchase order to every other related document in the transaction chain.

- Promote compliance with internal policies, negotiated contract terms, and legal regulations across your supply chain.

- Improve organizational processes through value creation and reduced total cost of ownership (TCO) for all purchases.

What Does a Purchase Order Tracking Sheet Look Like?

A purchase order tracking sheet contains all the necessary information to track a group of purchase orders in a spreadsheet format. Each PO is identified by its unique PO number and will have other associated fields such as date, description, item number, units, amount, price, and more.

A PO tracking sheet can be created manually or generated automatically by software. When done manually, these tracking sheets exist in a silo, typically in Excel, and can’t be easily searched or linked with outside systems.

![]()

How Do I Track a Purchase Order in Excel?

Using Microsoft Excel for purchase order management is easy to get started with but may prove difficult later on. That’s because when multiple users interact with the sheet, information is not easily or cleanly updated and shared.

Users will have to go into the spreadsheet at the same time and overwrite each other’s data as they update the sheet.

Excel may be suitable for a small business that only tracks a small amount of POs and only has a few people involved in the PO tracking process. However, as a company grows, so does the volume and complexity of PO tracking—making it nearly impossible to manage POs in Excel.

To track a purchase order in Excel, you’ll simply need to make a purchase order tracking spreadsheet like the one above. Create columns for each field, starting with PO number, then followed by fields like date, item #, description, etc.

If you want to get more granular, add fields like department, requester, and budget allocation. Example purchase order tracking templates can be found easily online like the ones found here and here.

From Excel, you can use formulas to calculate spend and even create graphs and charts based on your purchase order tracking sheet data. However, it will be challenging to integrate this data with other systems and enable other users to update and search the spreadsheet without the potential for data entry errors.

How Do I Track a Purchase Order in QuickBooks?

Quickbooks has a feature for companies to create purchase orders directly from the software but it is limited and does not cover approval workflows. Once those purchase orders have been created, users can view a list of purchase orders and record the items they’ve received.

Being able to view all open purchase orders in a list is a type of a PO tracking system, but it is somewhat limited as once POs are marked as received they are removed from this list. There are other methods of tracking orders after they’re marked as received, but it’s not as clean and simple as other PO tracking systems.

The other issue with using Quickbooks for PO order tracking is that not all business users are also Quickbooks users, as it is typically reserved for accountants.

People from other departments that are working on purchasing and budgeting might not have Quickbooks access and are then locked out of the PO tracking system. Often this causes bottlenecks because the finance team are required to create the PO and the relevant team don’t have access to the tracked data.

A dedicated purchase order tracking solution, like PLANERGY, will have integration options to integrate with integrate with QuickBooks Online or integrate with QuickBooks Desktop.

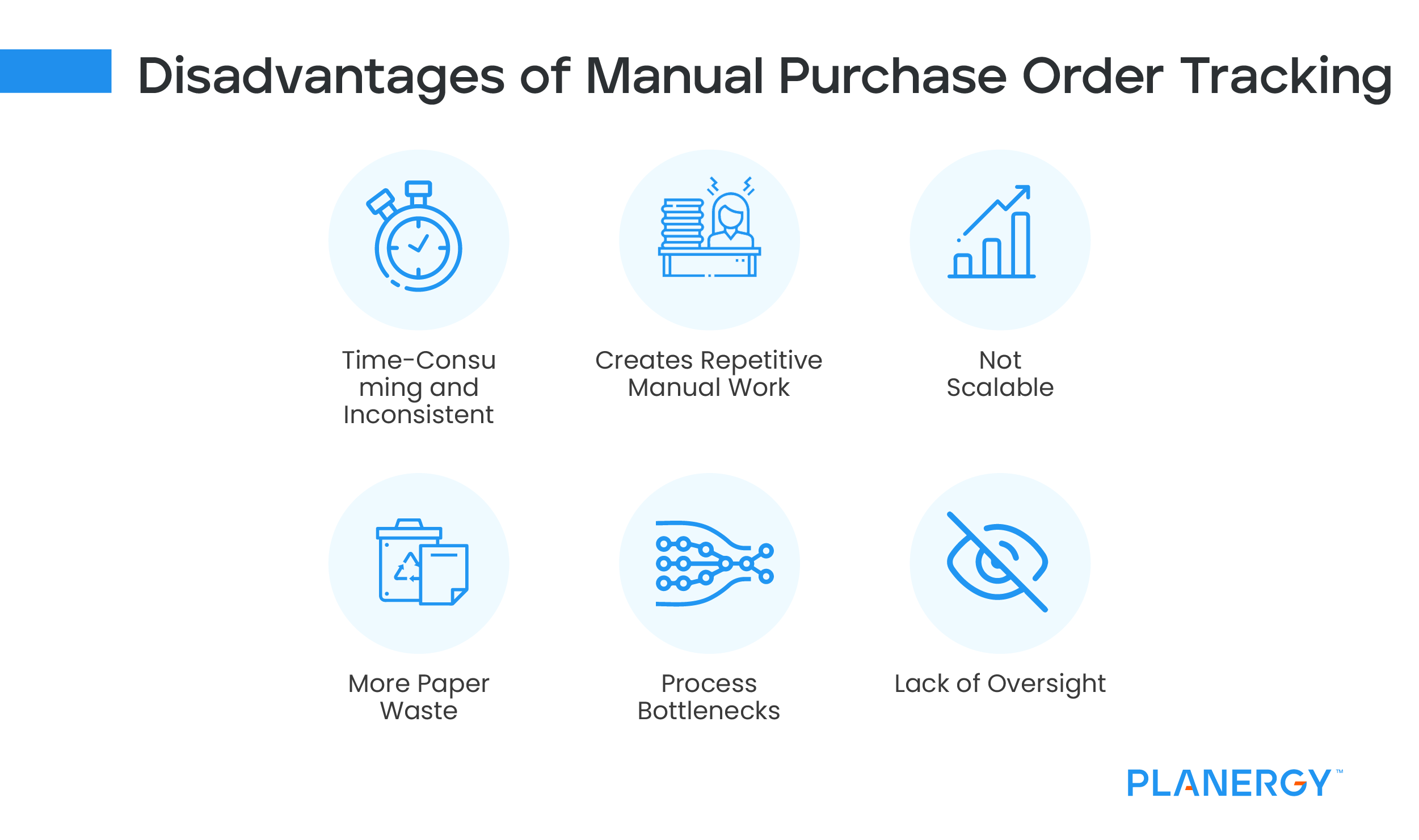

Disadvantages of Manual Purchase Order Tracking Methods

The traditional method of tracking purchase orders involves paper-based tracking, piecemeal software solutions, or some blend of the two. While they do improve efficiency and productivity compared to no PO tracking system, they create roadblocks to serious savings and create ongoing issues, including:

Time-Consuming and Inconsistent

Completing every step of PO tracking by hand is costly. Employees spend precious hours on data entry, error correction, and confirming important transaction details instead of higher-level, value-building tasks. In addition, manual work is more prone to error and omission.

Without automation, there may not be a consistent methodology, so no two employees may prepare, route, or file purchase orders the same way. This also makes it difficult to create ownership for specific roles and tasks—and the potential bottlenecks that can disrupt them.

Creates Repetitive Manual Work

Manual PO tracking requires more employees than automated PO tracking. These employees need to physically file and prepare purchase orders, a time-consuming process that encompasses a lot of repetitive data entry and increases the chance of human error (which then requires more repetitive tasks to correct).

Not Scalable

With manual PO tracking, payroll and material costs can grow to unmanageable levels as the number of purchase orders grows. Documents may be lost, misfiled, routed to the wrong party for approval, or sit unacknowledged for days, creating costly roadblocks.

This lack of organization can lead to “invisible spend”—creating surprising budget overruns, duplicate orders, and missed opportunities for discounts.

For modern companies, using automated purchase order software to speed up and improve their procurement processes makes sense. Automating these processes frees companies from the errors, delays, waste, and inconsistencies that paper-based POs bring.

More Paper Waste

Paper forms are expensive, difficult to create, correct, and store, and subject to human error. With paper, correcting a single error on a PO requires an employee to dig through drawers to find out what went wrong—surely time that could be better spent elsewhere.

Paper-based PO tracking contributes to the two pounds of paper used daily—and the 10,000 sheets of paper used every year—by the average office worker. Considering that up to 70% of office waste is paper, all those duplicate copies quickly add up to a Godzilla-sized environmental footprint.

Process Bottlenecks

When processing purchases manually there will often be bottlenecks created, if somebody forgets to carry out a step in the process everything grinds to a halt. A common example is with approval, especially when multiple steps of approval are required. If the approval is managed by email it is easy for an email to be missed and not responded to.

Lack of Oversight

With management of purchasing often siloed within departments it is difficult to enforce compliance with purchasing policies to ensure purchasing is done with preferred suppliers and that purchasing fraud does not become an issue.

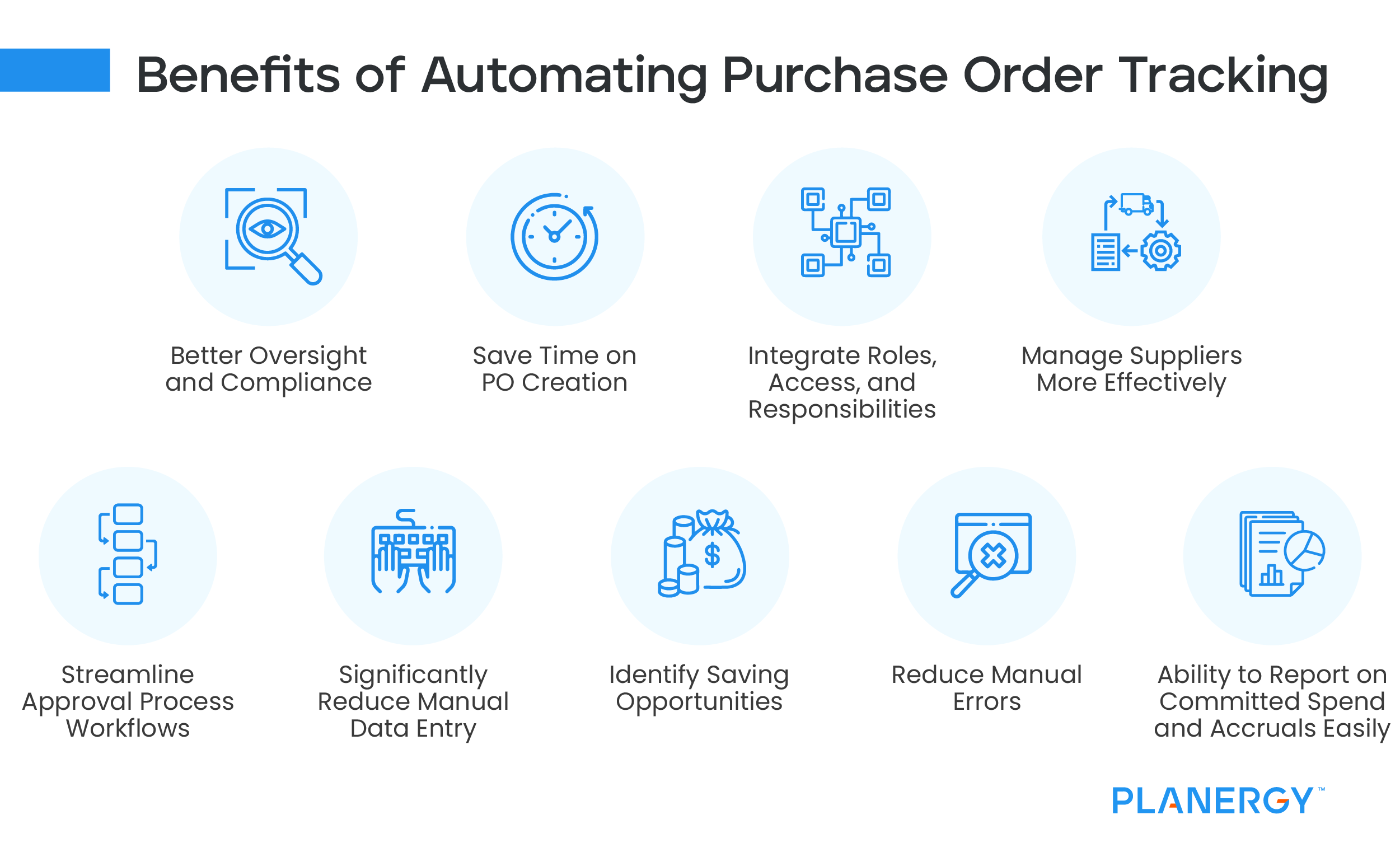

What Are the Benefits of Automating Purchase Order Tracking?

Purchase order tracking software provides customizable tools like purchase order templates and automated workflows to trim the waste from not just PO tracking but your entire procurement process.

It’s also backed up to the cloud, accessible via mobile devices, and some (like PLANERGY) harness the power of artificial intelligence.

Additionally, PO software integrations can be built with other systems including enterprise resource planning (ERP), customer resource management (CRM), and accounting software. This makes it easier for all departments to submit purchase requests, manage invoices and payments, gain insights from PO tracking, and add automation to existing processes.

Even without a large investment, PO software can give small businesses the same powerful toolkit typically reserved for larger enterprises, including ‘always-on’ access to the PO tracking system. Upgrading to automated, cloud-based PO management enables businesses to:

Better Oversight and Compliance

PO software provides a user-friendly procurement portal takes the guesswork out of buying while ensuring compliance and profitability. It can provide training and documentation on demand and enable real-time changes, additions, and corrections.

The portal can also answer key questions like where the PO is in the process, who requested it, and who approved it.

Save Time on PO Creation

With PO software, new purchase order forms can be created from templates that automatically populate vendor information, payment terms, contract specifics, and inventory management data—saving significant time and ensuring standardization.

Integrate Roles, Access, and Responsibilities

PO software enables companies to ensure proper rights and approval across the procurement process. If some users just need to submit purchase requests, then their role only allows them to do that—while others might have full admin rights and the ability to approve requisitions and sign-off on POs.

Manage Suppliers More Effectively

Preferred suppliers can be automatically selected on PO forms for everyday products (such as office supplies). Previous contracts can also be pulled to provide a list of vendors who provide the best pricing, delivery, and quality for one-off purchases.

Streamline Approval Process Workflows

No more random bottlenecks or POs lost in the paper approval flow. Real-time alerts and reminders for purchase order approval requests ensure purchases are made in a timely manner.

Significantly Reduce Manual Data Entry

PO software reduces data entry, exemption tracking, and other low-level work to free staff for more valuable tasks.

Identify Saving Opportunities

Procurement, vendor management, and accounts payable data can be unlocked for purchase order tracking, negotiation, strategic sourcing, and financial analysis—including reporting, projections, and detailed audit trails.

Reduce Manual Errors

When the bulk of the PO lifecycle is automated, risk exposure from human error, duplicate orders, rogue spending, and invoice fraud is greatly reduced.

Better Ability to Report on Committed Spend and Accruals

PO tracking software produces more actionable data that’s available in real-time. It enables companies to create reports for spend vs budget, committed spend, accruals, and more—helping with faster and more accurate financial closing at month and year-end.

Stay Competitive With Purchase Order Tracking Software

Staying ahead of the curve in today’s competitive business landscape means being ready to embrace what’s working—and jettison what isn’t. That means extracting value from your purchase orders, not just using them as a means to spend.

For example, with PO tracking software you’d be able to identify that your company is using seven different stationary suppliers. If that was consolidated to one or two suppliers (a backup is always prudent) you would be able to get lower bulk pricing and likely better service as a more valued customer.

Automation makes it easy to say goodbye to costly errors and wasted resources, as well as productivity-sapping paper-based processes. Changing how you track POs can be the spark that ignites truly powerful, smart, and streamlined procurement for your company—while giving you a competitive edge over those stuck in the past.