In the intricate world of procurement and supply chain management, choosing between centralized and decentralized purchasing systems is a critical decision that can significantly impact an organization’s efficiency and cost-effectiveness.

Understanding the nuances of each approach is essential for procurement managers and business owners aiming to streamline operations and maximize value.

What is Centralized Purchasing?

Centralized purchasing is a procurement strategy where a single centralized department or team manages all purchasing activities.

This approach consolidates purchasing power and decision-making, often leading to better-negotiated terms and cost efficiencies due to economies of scale.

Centralized procurement allows for uniformity and standardization across the organization, ensuring consistent quality and compliance with corporate policies.

It’s particularly advantageous for large organizations aiming for uniformity in supplier relationships and procurement processes.

What is Decentralized Purchasing?

Decentralized purchasing, on the other hand, empowers individual departments or business units to handle their own procurement activities.

This approach provides flexibility and responsiveness, as each unit can make purchasing decisions tailored to its specific needs and market conditions.

Decentralized purchasing can foster innovation and speed, allowing departments to react quickly to changes and opportunities.

It can be advantageous for organizations with diverse operations or those operating in multiple regions with varying local requirements.

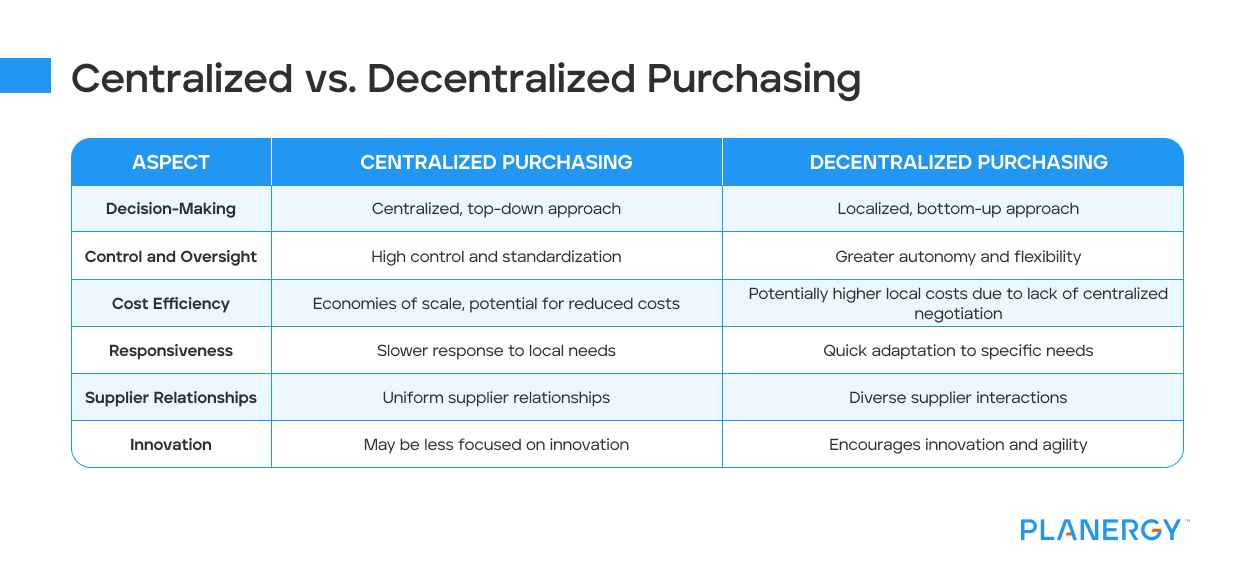

Centralized vs. Decentralized Purchasing

| Aspect | Centralized Purchasing | Decentralized Purchasing |

|---|---|---|

| Decision-Making | Centralized, top-down approach | Localized, bottom-up approach |

| Control and Oversight | High control and standardization | Greater autonomy and flexibility |

| Cost Efficiency | Economies of scale, potential for reduced costs | Potentially higher local costs due to lack of centralized negotiation |

| Responsiveness | Slower response to local needs | Quick adaptation to specific needs |

| Supplier Relationships | Uniform supplier relationships | Diverse supplier interactions |

| Innovation | May be less focused on innovation | Encourages innovation and agility |

Advantages of Centralized Procurement

Cost Savings

Organizations can leverage bulk purchasing and negotiate better discounts with suppliers by consolidating purchasing power.

This approach allows for economies of scale, where the cost per unit decreases as the quantity purchased increases.

As a result of the better pricing, businesses can achieve substantial savings, which can be reinvested into other areas of the organization.

Standardization

Businesses can standardize products, services, and processes with a single procurement team.

This uniformity helps maintain high standards and adherence to corporate policies, reducing the risk of discrepancies and non-compliance.

Standardization also simplifies training and onboarding for new staff members, as procedures are consistent across all departments.

Streamlined Processes

With centralized purchasing, organizations can streamline their procurement processes, reducing duplication of effort.

A single, cohesive team manages all purchasing activities, leading to more efficient workflows and better coordination.

This approach minimizes the administrative burden on individual departments, allowing them to focus on their core functions.

Streamlined processes also enable better tracking and management of purchases, enhancing overall operational efficiency.

Disadvantages of Centralized Purchasing

Slower Response

A potential drawback of centralized purchasing is the slower response to local needs.

Since decision-making is concentrated in a single department, addressing specific requirements of individual departments or regions may take longer.

This delay can be problematic in dynamic environments where quick action is necessary.

The centralized approach may struggle to keep pace with rapidly changing local conditions or urgent demands.

Potential Bottlenecks

Centralized decision-making can lead to bottlenecks with order fulfillment, especially when approvals and authorizations are required from a single point of contact.

This concentration of control can create delays and hinder the timely execution of procurement activities.

Bottlenecks can also arise from overburdening the central team with numerous requests, leading to inefficiencies and frustration among departments waiting for their needs to be addressed.

Reduced Flexibility

Centralized purchasing often results in reduced flexibility at the local level. Individual departments may have limited autonomy to make purchasing decisions tailored to their specific needs.

This lack of flexibility can stifle innovation and prevent departments from quickly adapting to unique market conditions or opportunities.

As a result, the organization as a whole may miss out on potential benefits that come from more agile, localized decision-making.

Advantages of a Decentralized Purchasing Model

Flexibility

Decentralized purchasing offers greater flexibility, allowing individual departments to adapt quickly to changing local conditions.

Each unit can make procurement decisions that best suit its specific needs and market dynamics.

This adaptability enables departments to respond promptly to opportunities, challenges, and changes, fostering a more dynamic and responsive organizational environment.

Empowered Teams

Decentralized purchasing encourages accountability and innovation by empowering local teams to handle their own procurement activities.

Departments take ownership of their own purchasing decisions, which can lead to more creative and effective solutions.

Empowered teams are often more motivated and engaged, as they have the autonomy to drive their initiatives and directly contribute to their unit’s success.

Quick Decision-Making

Decentralized purchasing facilitates faster decision-making, as departments do not need to wait for approvals from a central authority.

This agility is particularly beneficial in fast-paced environments where timely responses are crucial.

Quick decision-making can enhance operational efficiency, reduce lead times, and improve customer satisfaction by promptly meeting their needs.

Disadvantages of Decentralized Purchasing

Inconsistent Standards

A significant disadvantage of decentralized purchasing is the potential for inconsistent standards across different departments.

Without a central authority to enforce uniformity, there may be variations in quality, compliance, and procurement processes.

This inconsistency can lead to challenges in maintaining cohesive organizational standards and managing supplier relationships effectively.

Higher Costs

Decentralized purchasing may result in higher costs due to a lack of centralized negotiation and bulk purchasing power.

Individual departments may not have the same leverage as a consolidated purchasing team, leading to less favorable terms and higher prices.

Additionally, decentralized procurement can result in duplicated efforts and resources, increasing operational costs.

Duplication

Another drawback of decentralized purchasing is the possibility of redundant efforts.

Different departments may independently source similar products or services without coordinated procurement activities, leading to inefficiencies and wastage, which makes inventory management more complex.

This duplication can strain organizational resources and hinder the overall effectiveness of procurement strategies.

Pros and Cons in Supply Chain Management

When it comes to supply chain management, both centralized and decentralized purchasing have specific pros and cons.

Centralized purchasing can lead to a streamlined and consistent supply chain, which can be advantageous for maintaining uniformity and predictability.

However, it may struggle to provide the flexibility needed to address unique regional or market-specific demands.

Conversely, decentralized purchasing can enhance supply chain agility, allowing quick responses to market changes.

Yet, it might suffer from a lack of cohesion and higher operational costs, affecting overall efficiency.

Why You Might Need Centralized Purchasing for Your Organization

Centralized purchasing can offer significant advantages for organizations seeking uniformity, cost efficiency, and streamlined operations.

By consolidating purchasing decisions, businesses can achieve greater control over budgets and maverick spending, leverage better deals from local suppliers, and maintain consistent quality across all units.

This is particularly beneficial for organizations operating in stable environments where standardization is key.

Hybrid Procurement Strategy

A hybrid procurement strategy combines centralized and decentralized purchasing elements to leverage each approach’s strengths.

By integrating a centralized framework for critical purchasing categories, organizations can maintain cost efficiencies and standardization while allowing individual departments the flexibility to procure unique items or services that cater specifically to local market conditions or operational needs.

This dual approach enables organizations to respond swiftly to changes, fostering innovation at the local level while still obtaining the benefits of consolidated purchasing power.

Implementing a hybrid strategy requires clear communication and well-defined processes to ensure alignment between central and local procurement teams.

This may involve establishing guidelines for which categories of purchases are handled centrally versus those that can be managed locally.

Additionally, regular collaboration and data sharing between departments can help identify opportunities for collective purchasing and innovation, ultimately improving organizational efficiency and responsiveness.

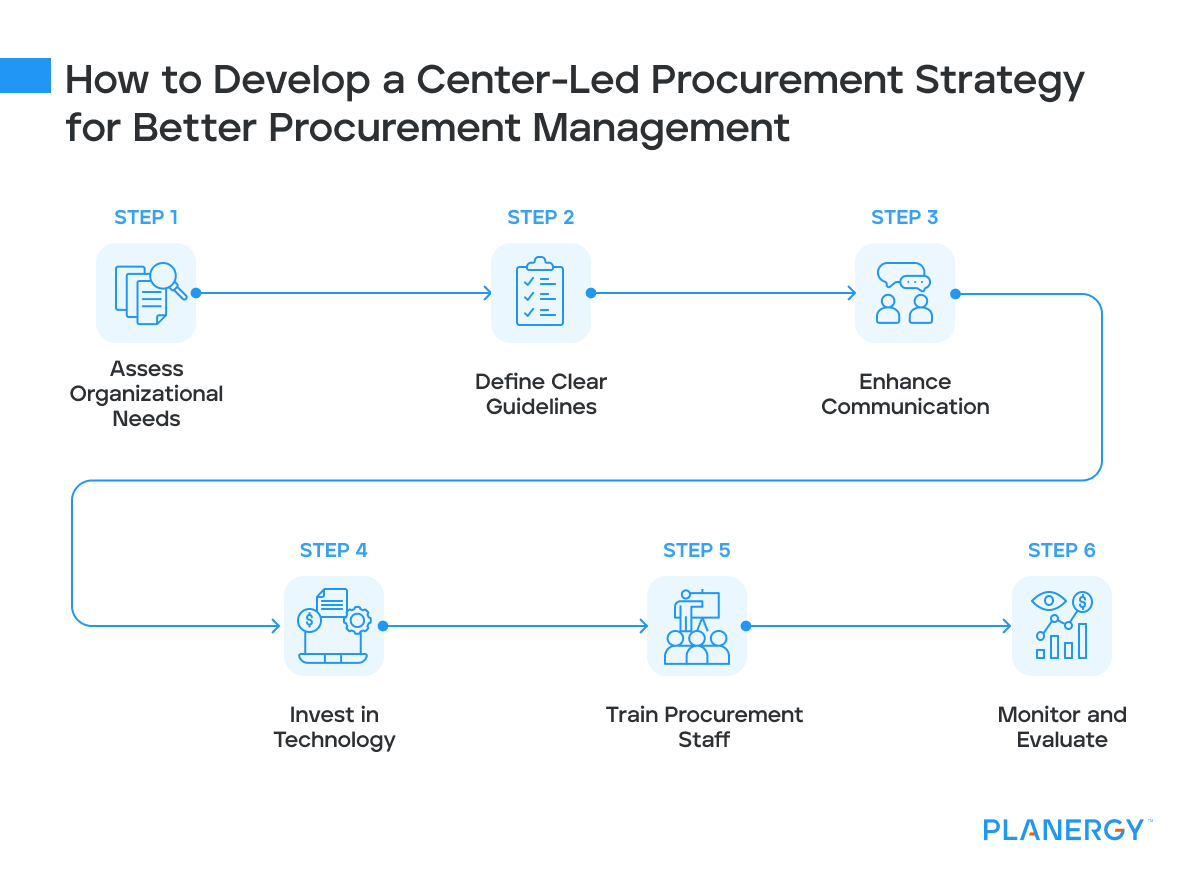

How to Develop a Center-Led Procurement Strategy for Better Procurement Management

Developing a center-led, also known as hybrid, procurement strategy requires a systematic approach to balance centralized and decentralized purchasing advantages.

Here are essential steps to consider as you develop your new purchasing processes:

Assess Organizational Needs: Begin by evaluating the specific needs of various departments and identifying which categories of products or services would benefit from centralized purchasing versus those that need local flexibility.

This assessment will guide the development of effective procurement pathways.

Define Clear Guidelines: Establish explicit criteria to delineate which purchasing categories will fall under centralized control and which will allow for decentralized decision-making.

This clarity helps prevent overlap and confusion among departments.

Enhance Communication: Foster strong communication channels between central and local procurement teams.

Regularly scheduled meetings and updates can ensure alignment on objectives, share insights, and identify collaborative opportunities for collective purchasing.

Invest in Technology: Implement procurement system software that facilitates visibility, real-time data sharing, and streamlined processes across all departments using automation where appropriate.

Technology is vital in tracking purchases, managing supplier relationships, and providing analytical insights.

Train Procurement Staff: Provide comprehensive training for both central and local procurement teams to ensure understanding and proficiency in the hybrid model.

Focus on collaboration techniques, negotiation skills, and adherence to compliance standards.

Monitor and Evaluate: Continuously monitor the effectiveness of the hybrid procurement strategy by measuring key performance indicators related to cost savings, supplier performance, and responsiveness to local needs.

Regular evaluations of the strategy will allow for adjustments and improvements to optimize procurement activities.

Empower Your Purchasing Department with a More Flexible Procurement Model

Consider integrating centralized purchasing in your organization to harness these benefits or combine elements of both systems to tailor a hybrid approach that meets your specific needs.

With software like PLANERGY, your procurement department can quickly and easily manage the entire procure-to-pay cycle with efficient contract management, spend analysis, and more.