Many organizations are starting to evaluate their purchasing processes and are finding new types of e-procurement tools to meet their needs.

The procurement process involves the following steps:

- Identifying and anticipating material or service needs

- Evaluate potential suppliers

- Selecting suppliers

- Releasing and receiving purchase requirements

- Continuously measuring and managing supplier performance

The stages may vary from one organization to the next, depending on whether purchasing is sourcing a brand new or repetitively purchased item and also whether there is a detailed approval process required for purchases that are above a certain dollar threshold.

New items require that the procurement department spend more time upfront evaluating potential sources.

Repeat items usually have some approved sources readily available. Even still, it is essential to review existing purchase contracts for compliance and make sure you are getting the best possible deal on the products and services you use most often.

In the past, preparing and managing the necessary purchasing documentation has been a time-consuming process.

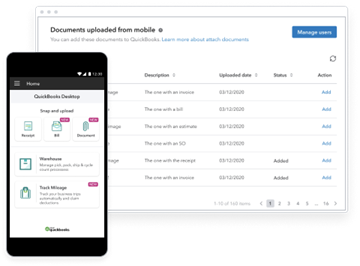

Many firms have streamlined their document flow process to reduce costs and the amount of paperwork handling required for all the purchases by moving to e-procurement tools.

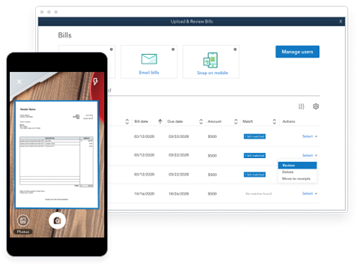

E-procurement software makes it easier to manage the flow of documents through automation and electronically generating and transmitting any purchase-related documents to suppliers.

The procurement platform helps streamline business processes by speeding up the procurement cycle.

Benefits of E-Procurement Software

The benefits of an e-procurement process include:

- Eliminating paperwork and paperwork handling

- Spending less time between recognizing a need and the release and receipt of an order

- Fewer errors

- Improving communication with suppliers and within the company. Better supplier relationships throughout the supply chain make more room for profit.

- Reducing overhead costs for the purchasing department

- Procurement professionals can spend less time processing purchase orders and invoices, which gives them more time to focus on strategic sourcing.

Ultimately, though you do have to invest in procurement applications, it will pay for itself with the cost savings you achieve in multiple areas.

You’ll get real-time visibility into spending so you can make sure you’re staying on budget. You’ll be able to get a handle on maverick spending and encourage your staff to make purchases from the available online catalogs.

Since everything is automated, there’s no need to worry about losing paperwork or waiting for approvals to come down from someone who’s out of the office on vacation.

Traditional procurement is much more expensive because of the room for error, the labor costs, and the lack of spend visibility.

E-procurement solutions are highly flexible and customizable to meet your business needs. No matter what your purchasing process or approval workflow looks like, you can make it work for you.

How the E-Procurement Process Works

The e-procurement process is highly similar to the manual procurement process but moves much faster.

User Needs Products or Services

The purchasing process starts with finding or anticipating a material or service user needs.

They use electronic documents such as purchase requisitions, stop checks, routine reordering systems (such as barcodes) or forecast and customer orders to determine the need.

Sometimes, material requirements identified during new product development also facilitate purchase needs.

Purchase Approval (and Supplier Evaluation)

Depending on the size and nature of the purchase, there may be various steps at this stage.

If this purchase is new, a supplier evaluation occurs to determine which supplier is the best option for the company.

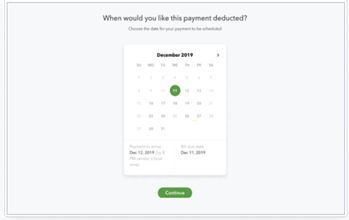

If this is a product or service that has been purchased before, the supplier may already be determined, but department heads and other individuals may need to approve the purchase before sending a purchase order to the vendor.

In the case of small purchases, such as office supplies, e-procurement systems often allow purchase requisitions with small requests to purchase the item without approval from another person in the company.

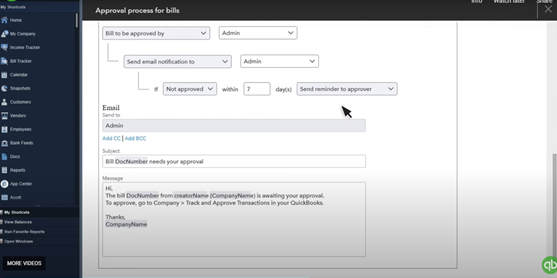

In cases where a dollar amount exceeds the user’s permission to generate a purchase order, the purchase requisition automatically goes through the necessary approval process before becoming a purchase order.

If a purchase requisition requests an item for a higher dollar amount that does not have an existing supplier, then the procurement department may obtain quotes or bids from potential suppliers.

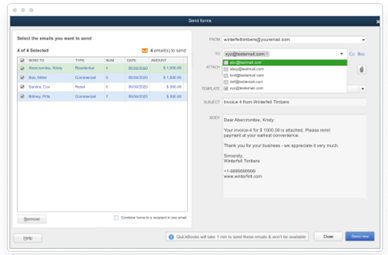

Purchasing forwards the request for quotation (RFQ) or request for proposal (RFP) to suppliers and invites them to submit a bid for a purchase contract.

For larger purchases, a detailed evaluation may be required. This happens after determining a purchase need exists, and the development of material specifications occurs.

For routine and standard product requirements with established suppliers, supplier evaluation and selection is not necessary, and the approval process may proceed.

However, any potential sources for new items, especially those that are complex, require a thorough investigation to be sure that procurement only evaluates qualified suppliers.

Bidding, Negotiation and Supplier Selection

This step only takes place for purchases that do not have an existing supplier, or when an existing supplier is no longer able to meet your needs.

The final supplier selection occurs once the procurement department has completed the required activities during the evaluation process.

Choosing suppliers is one of the essential activities because errors made in this phase of the purchasing cycle can cause significant damage to the bottom line and take a long time to rectify.

After bids have been received and negotiation has occurred, the procurement team selects the supplier and moves on to authorize the purchase through the purchase approval process, which is automated with the e-procurement system.

Purchase Approval

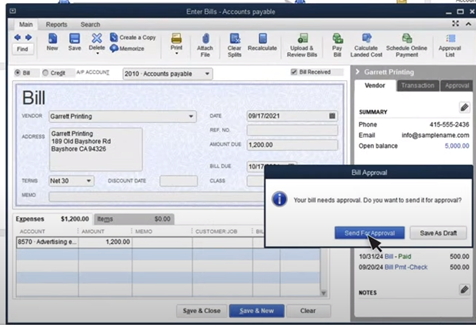

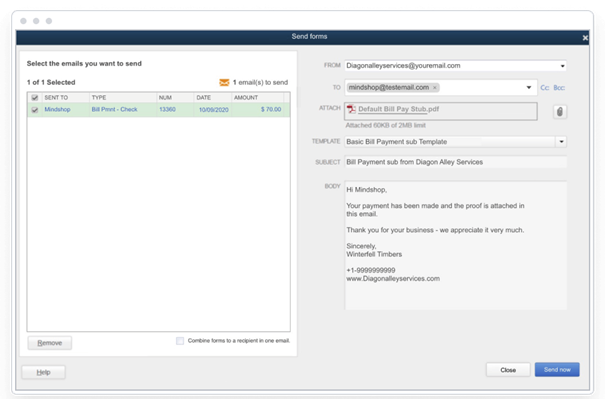

Once the supplier has been selected, or a requisition is received, purchasing grants purchase approval, by creating an electronic purchase order.

PLANERGY allows users to create purchase requisitions that automatically go through an approval process based on approval rules created during setup.

Once the purchase requisition is approved, it automatically converts to a purchase order to save time and effort.

The purchase order details all of the critical information about the purchase, including the quantity, items, quality requirements, price, delivery method, delivery date, purchase order number, order due date, and the ship-to address.

Release and Receive Purchase Requirements

In this phase of the purchasing cycle, the purchase requirements are physically transmitted. Some organizations opt to submit orders electronically, what other sin material releases by mail or fax.

Using electronic data interchange (EDI) can help shorten the order cycle time.

The shipping and receiving processes require several other relevant documents, which can also be made electronic such as the bill of lading, the material packing slip, and the receiving report.

Continuously Monitoring Supplier Performance

You should never assume that because you found the best possible supplier for a particular product last year that they will always be the best possible supplier for your needs.

One way to make sure you are consistently working with the best suppliers is to track their performance after awarding them a contract.

If you find that they are consistently late with their deliveries, or short on their quantities and have other issues then obviously they are affecting your ability to conduct business with your customers.

It’s essential to invest in continuous measurement to identify Improvement opportunities or cats when suppliers are not holding their end of the bargain.

If you do not have a formal evaluation in place, you have little insight into the supplier performance over time.

If you don’t have the evaluation system, you don’t have the data necessary to support future purchasing decisions.