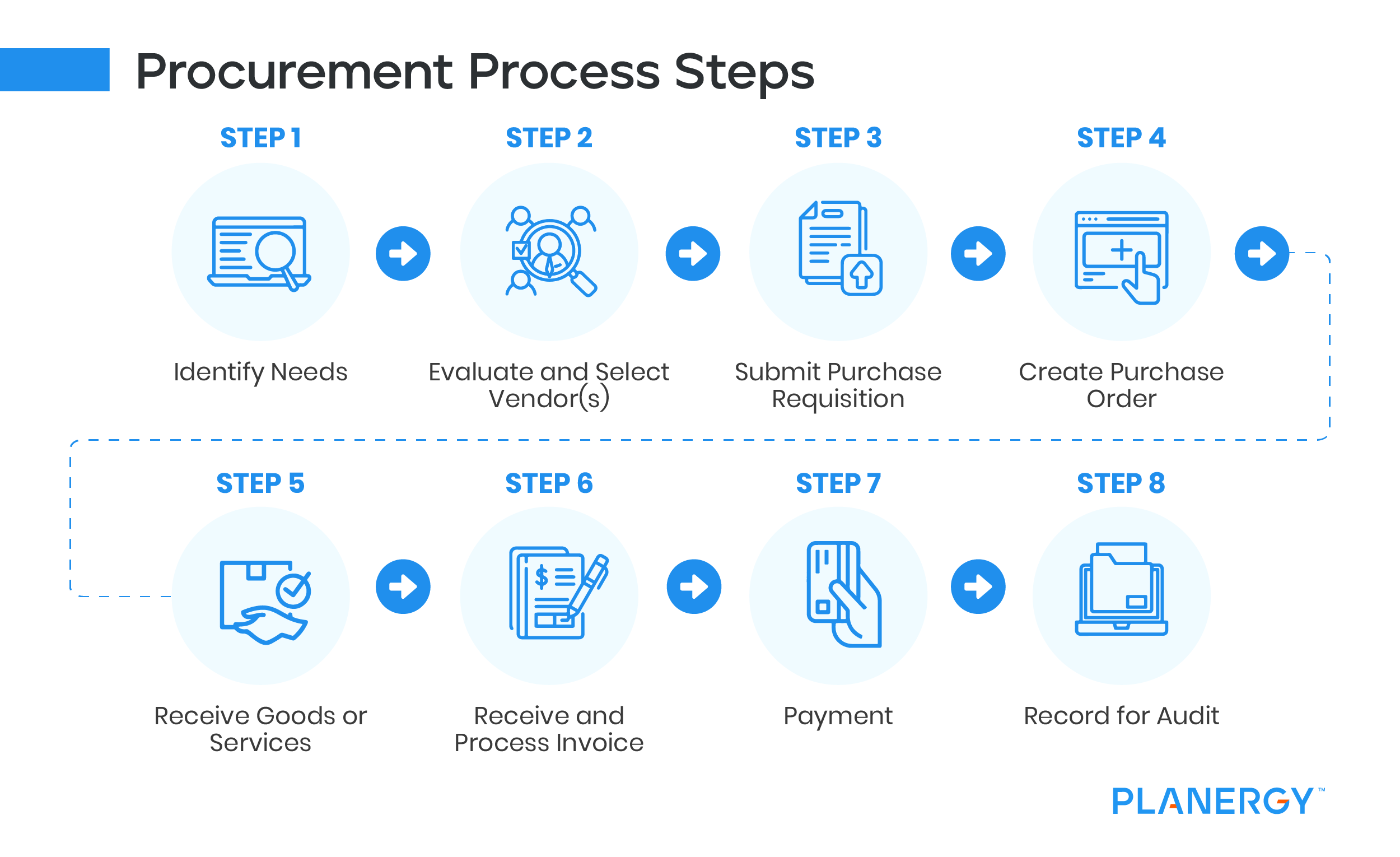

Identify Needs

The procurement process begins with a need for goods or services.

This can be an internal need—meaning any materials required to run the business, or external—materials that the business will eventually sell. This stage also includes setting a budget.

For example, let’s use an auto tire distributor that’s running low on a particular type of tire.

In this stage, they would determine which tire they’re low on, how many they need, when they need them by, and how much they should cost.

Evaluate and Select Vendor(s)

This stage is for sourcing vendors and determining their ability to provide the best value and quality.

It’s important to find vendors who not only deliver a high-quality product for a competitive price but who have a strong reputation.

Doing so will set you up with a sustainable supply chain for the long haul.

Creating a mutually beneficial relationship that lasts for the long term is ideal. The best practice for finding vendors is known as strategic sourcing, which takes a proactive approach to vetting preferred suppliers for key purchases long before they take place.

During this stage, our tire distributor would make a list of suppliers that provide the type of tire they need.

The selection criteria would weigh cost, quantity, reputation, speed of service, dependability, and customer service.

They may also send a request for quote (RFQ) to several suppliers to get quotes and compare options.

Sub-processes in this stage may include tendering, bid management, compliance checks, contract management, and supplier relationship management. Once all criteria have been evaluated, it’s time to select the best vendor for the purchase.

Submit Purchase Requisition

The next stage in the procurement process is putting in a purchase request to get internal approval to make a purchase. This includes creating a purchase requisition form and submitting it to the department that’s responsible for the finances. This could be the procurement team or other managers who control the budget.

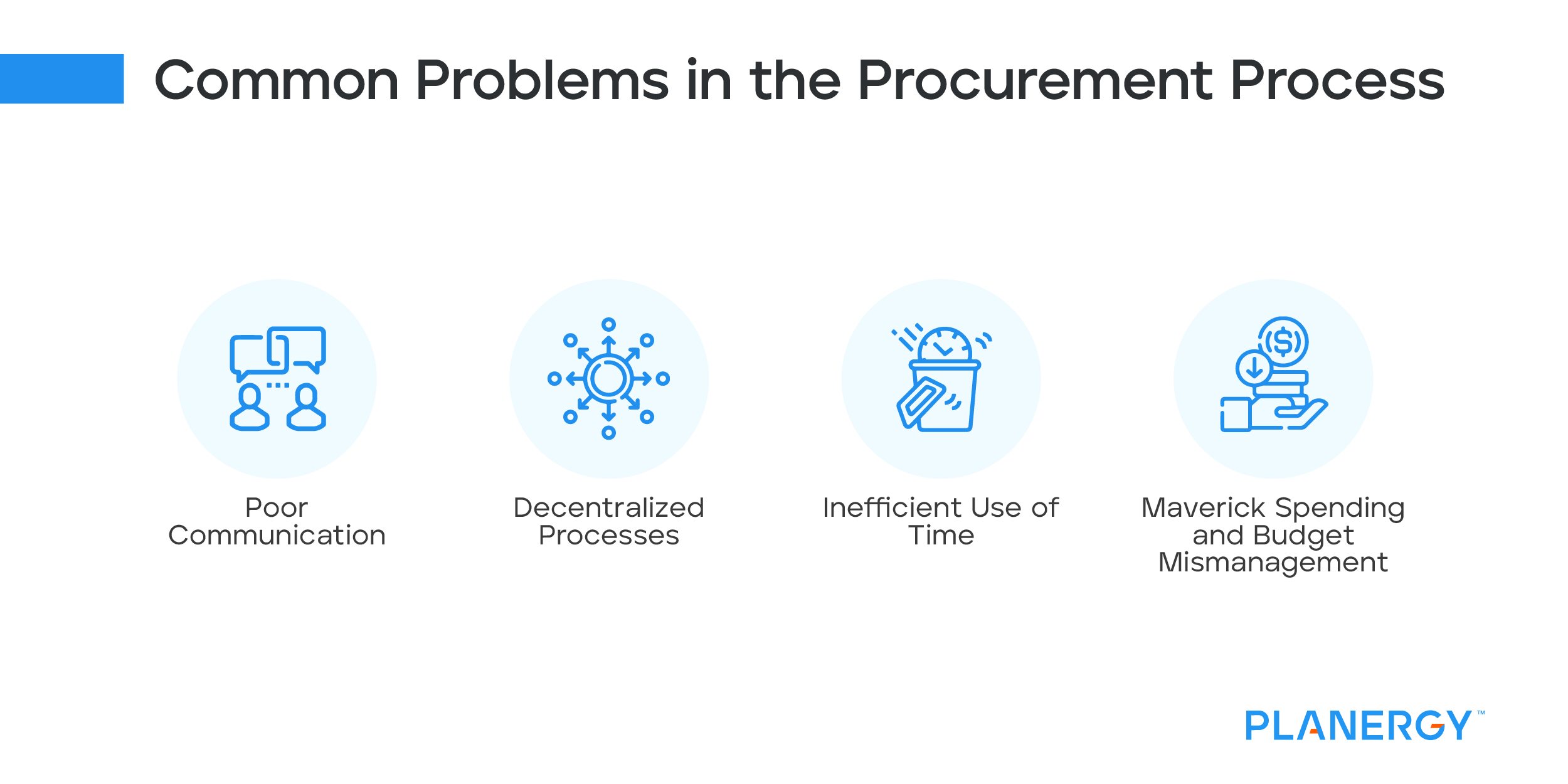

When using manual processes like paper forms, this stage creates the first potential roadblock in the procurement cycle.

Managing approvals without centralized digital processes can cause requests to be put on the back burner or slip through the cracks as papers are stacked in growing piles or emails are ignored.

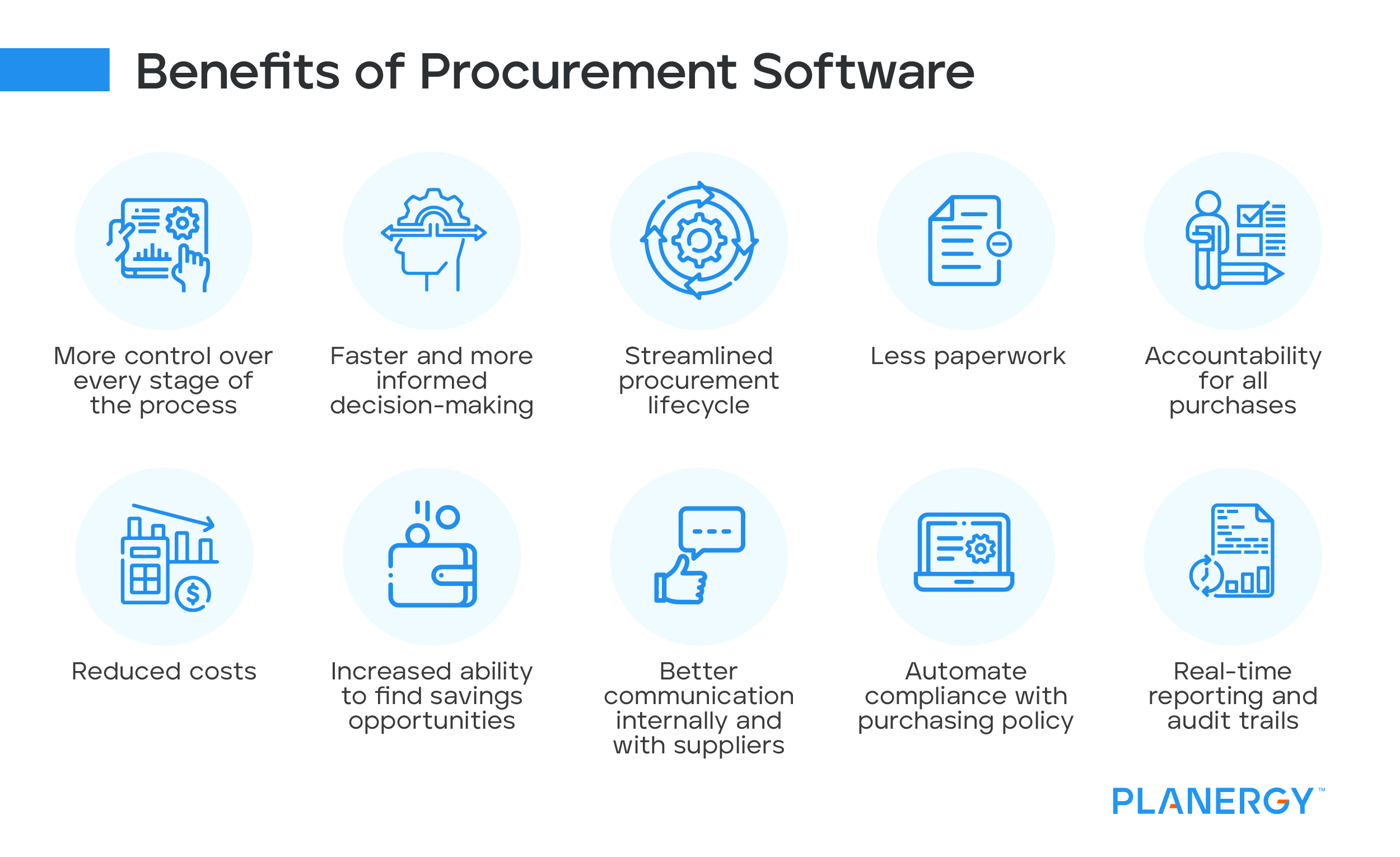

With modern procurement software, purchase requisition are sent to the proper parties automatically.

Crucial information can instantly help management decide how best to leverage preferred vendors and gain the best value for each purchase. Approvers can also reject a request quickly and request more information if needed.

The tire supplier would share the following information with purchasing for their approval:

- Store name

- Quantity and description (30 winter tires, size 215)

- Vendor name (e.g. Firestone®)

- Price ($1,500)

The tire supplier would then share this document directly with the purchasing department for approval, rejection, or further discussion.

Create Purchase Order

Once the purchase requisition is approved, the purchasing team submits a purchase order (PO) to the vendor.

Purchase orders contain all the information a vendor needs to fulfill and deliver the order, including payment terms.

Once accepted and signed, they become a legally binding document that ensures the vendor will deliver and the purchaser will pay.

Purchase orders are typically created through Word or Excel templates, digital purchasing systems, or full Procure-to-Pay software like PLANERGY, which enables businesses to submit digital POs and easily track their acceptance by vendors.

Our tire supplier’s purchase order would include:

- Purchasing company name (ABC Tire Company)

- Unique purchase order number (345)

- Description and quantity (30 winter tires, size 215)

- Price ($1,500)

- Mailing address (15 Fake Lane, Sacramento, CA, 12345)

- Payment information and terms (to be paid in 45 days via wire transfer)

- Invoice address (could be the same as mailing address)

Before sending a purchase order, buyers should verify funds are available to cover the purchase.

This process is greatly simplified with clear roles, buying limits, and authorization hierarchies—all of which are built into PLANERGY.

Receive Goods or Services

Once the PO is confirmed, the vendor is able to deliver the goods or services ordered. Because the PO is a legally binding document, the vendor can deliver goods or services before receiving payment.

When the purchaser receives the goods or services they ordered, they have a limited amount of time to notify the vendor of any issues.

Sometimes, the invoice and the order arrive at the same time. In other cases, the invoice will arrive before the goods or services are delivered.

Receive and Process Invoice

The vendor sends an invoice to the purchaser that describes what the order includes. The invoice also confirms the sale and states when payment is due.

Three documents— purchase order, order receipt, and invoices—are aligned and reconciled in a process called three-way matching.

This process finds any discrepancies and ensures that what you are being charged matches what you have received.

Payment

Once the invoice and order have been received and approved via three-way matching, the accounts payable team will process the invoice for payment.

On the invoice, the vendor will provide payment details (such as account numbers for a wire transfer).

The accounts payable team must pay within the agreed-upon time frame or face a potential late payment fee.

AP automation software can streamline the payment process, making it easier to avoid late payment fees and capture early payment discounts, if the vendor offers them.

Record for Audit

Once payment has been processed, the buyer records the completed transaction for the company’s financial records. This final stage in the procurement cycle is important for bookkeeping and preparing for future audits.

Auditors require thorough documentation for all purchases, so documents from purchase requisition through invoice should be stored in one central location. With eProcurement software, the transaction is recorded automatically and made available for review at any time.

Having this information in a centralized database makes reporting, forecasting, and audit trails much simpler to manage.