Businesses will always need to purchase goods and services to meet their needs.

Using a formalized purchasing process to do so can extract the maximum value from every dollar spent.

The way a company executes its purchasing process can have a major influence on not just expenses, but competitive performance, profitability, and efficiency.

By learning and implementing a few best practices for your purchasing process—particularly with help from modern procurement software—you can help reduce waste, protect against needless risk and expense, and maximize efficiency, profits, and value recovered from every dollar invested.

What Is Purchasing?

Purchasing is the practice of purchasing goods and services. Sounds obvious, but it can get confused with other areas of procurement.

To be more specific, purchasing is part of the procurement process that involves making the actual purchase.

It includes identifying a need, getting internal approval, and sending a formal purchase order (PO) to vendors.

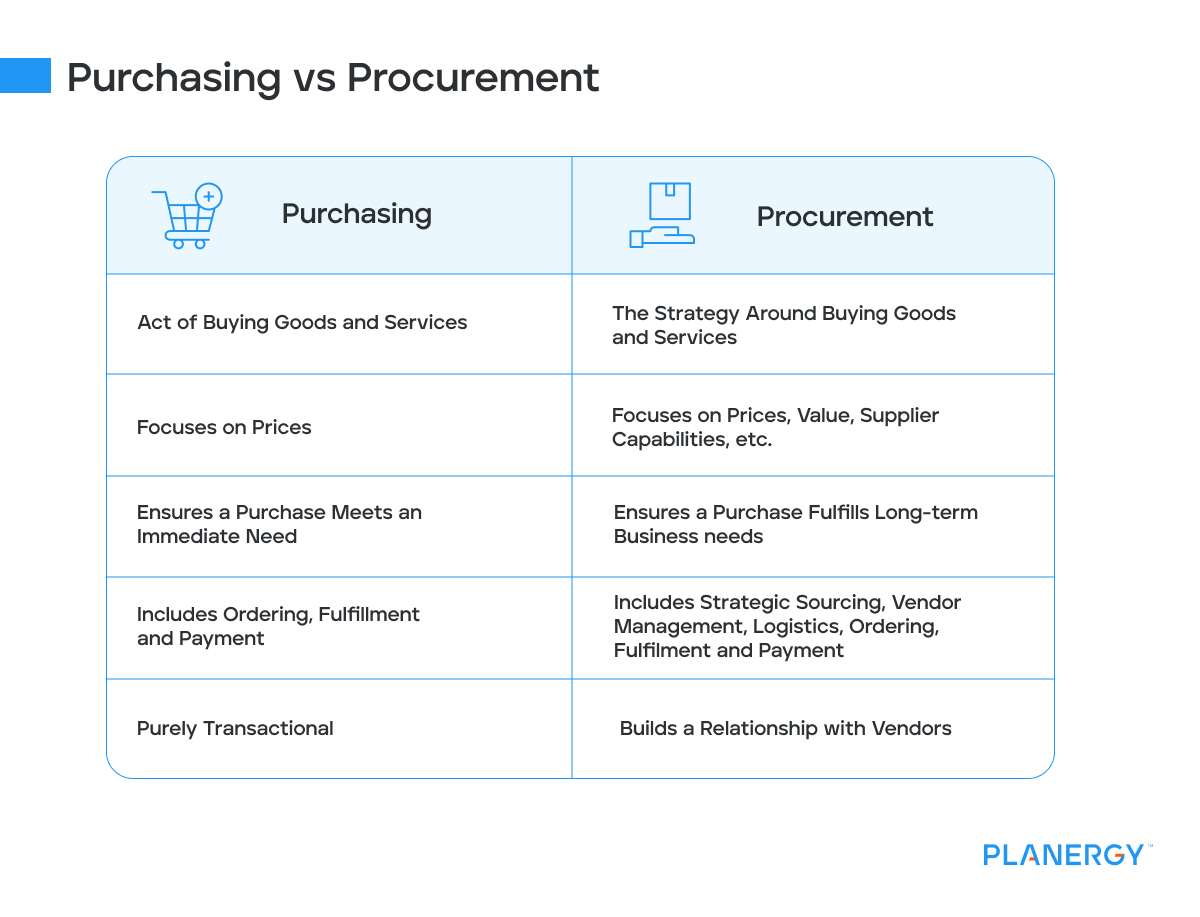

What Is the Difference Between Purchasing and Procurement?

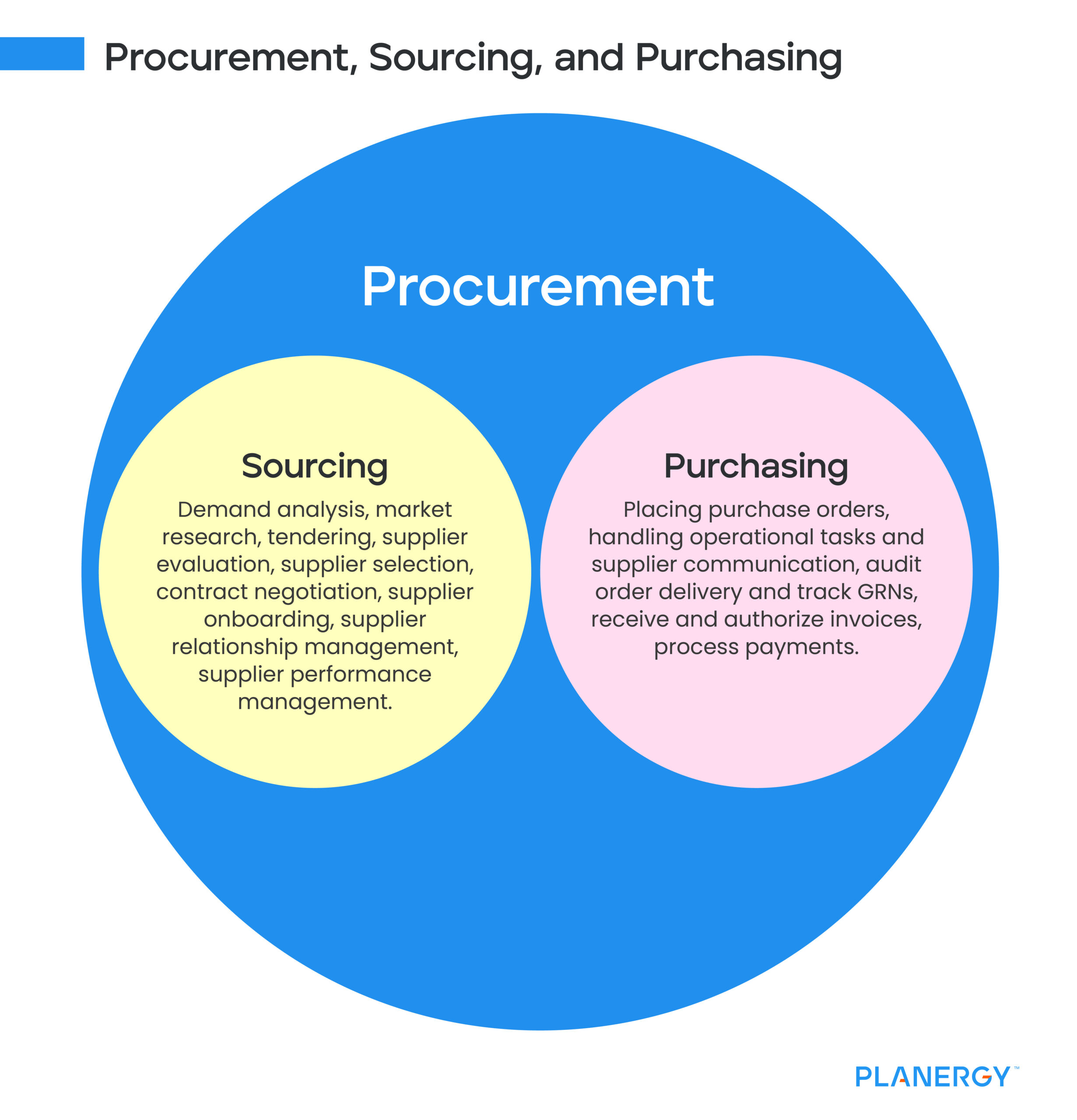

The difference between purchasing and procurement is that purchasing is actually just a part of the greater procurement process.

While procurement is the entire process from sourcing through accounts payable, purchasing is the part where needs are met through purchasing goods and services.

The greater procurement process is referred to as procure-to-pay (P2P).

Procurement involves all of the P2P process, including sourcing and vetting suppliers, negotiating yearly contracts, and ensuring that vendors are paid on time.

Purchasing teams focus solely on the purchasing part of the P2P process.

Another way of looking at it is that procurement refers to the overall framework for optimizing purchasing for maximum value, savings, and efficiency while purchasing is confined to actually obtaining goods and services.

Procurement will also incorporate all sourcing activities as well as purchasing.

What Is the Purchasing Process?

The purchasing process is the steps a company goes through when purchasing goods and services.

When looked at as a whole, the purchasing process is better described as the procure-to-pay (P2P) process. At its most basic level, the process can be as simple as conducting a transaction.

In the P2P process, procurement teams requisition goods and services through your supply chain, much in the same way a consumer might research and purchase the best appliance for their home.

The main benefit of a formal purchasing process is avoiding waste due to fraud, maverick spend, and other non-optimized buying habits.

By setting clear procurement policies and procedures, companies can ensure consistency, reduce costs, and improve supplier relationships, leading to better negotiation power and overall efficiency.

Additionally, integrating analytics into the P2P process allows for real-time tracking and data-driven decision-making, further enhancing operational effectiveness.

Whether you’re a small business or a multinational corporation, having a formalized purchasing process can help you stay competitive in the modern marketplace.

Incorporating software that implements guided buying can ensure compliance with purchasing policies and maximize realized cost savings and cost avoidance.

Manual workflows and paper-based record-keeping are no longer sufficient for modern purchasing processes. Procurement software and automation have eliminated the challenges that come with these outdated methodologies.

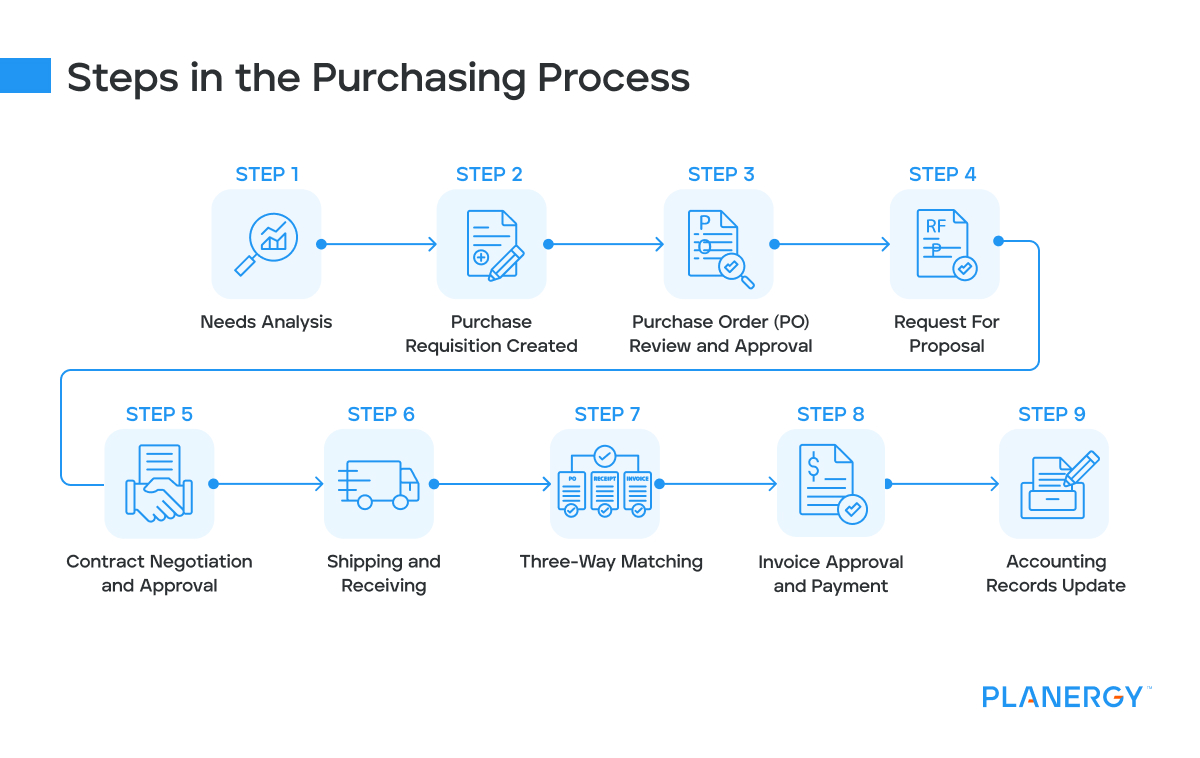

What Are the Steps in the Purchasing Process?

The steps in the purchasing process are a cycle, with each step requiring information to be exchanged and either internal or external approval to move forward.

Every business will have its own unique purchasing process, but the purchasing process below is a standard that many companies can follow, and is a great place for any company to start.

Needs Analysis

Before a purchase can happen, a business need must be identified. The need should solve a specific problem and be documented by either the purchase requester or the procurement team. The procurement team can work with other teams on how to best justify a need and document it.

For example, a company that has recently adopted a remote-first policy may need more advanced video conferencing software.

The operations team might identify and source the best tool themselves, or can work with procurement to understand and document exactly what is needed and why before sourcing the best tool.

Purchase Requisition Created

Once a need has been identified, a purchase requisition is submitted to either the procurement department or purchasing manager of the department making the request.

The purchase requisition form contains full details on the items or services to be obtained, including the justification for why they need to be purchased from the needs analysis.

When using a procurement software system, an important step of the requisition process can be automated. If the requisition is below a certain threshold and there is budget available, the purchase request can be automatically approved.

If it is above that threshold, it can get automatically routed to the necessary approvers for expedited processing.

Purchase Order (PO) Review and Approval

Once the requisition is approved, it gets turned into a purchase order (PO). This can also be automated with e-procurement software, or done manually with Excel, Word, or a paper form.

Rejected purchase requisitions are returned to the requester to ask for a correction or clarification on why the purchase can’t be made.

The purchase order contains everything a vendor needs to fulfill the order, including quantity, price, item number, payment information, and payment terms.

The procurement team should review purchase orders to ensure that they include accurate pricing and match the purchase requisition.

They also need to verify the funds exist in the appropriate budget to cover the purchase.

This can be done by sending the purchase order to accounting, but if procurement software is being used, the budget should be immediately available for procurement teams to verify. This helps simplify the purchase order process.

Requests for Proposal

In some cases, approved POs are sent to the procurement department and used to create either an RFP (request for proposal) or RFQ (request for quotation). These, or some other sourcing documents, can be used in a sourcing event.

These requests are dispatched to potential vendors to solicit bids. Vendors are carefully reviewed based on important characteristics such as performance history, compliance records, average lead times, reputation, and price.

Note: When purchasing routine goods or services from preferred suppliers that have already been vetted, this step and the next can be skipped. Steps four and five are more important when working with new suppliers.

Contract Negotiation and Approval

If the RFP or RFQ process is used, the vendor with the winning bid is awarded a contract. The contract is further refined to ensure optimal terms and conditions and a mutually satisfactory arrangement for both parties.

Once the contract is signed, the purchase order becomes a legally binding agreement between the buyer and seller when the supplier accepts it.

This gives both parties recourse in the event that the order is not delivered by the vendor or paid for by the customer.

Shipping and Receiving

The supplier delivers the goods or services within the agreed-upon timeframe. Relevant documentation, like a goods received note for goods or timesheets for services, can be tracked and recorded as evidence for future audits.

Once they’ve been received (in the case of goods) or performed (in the case of services), the purchaser reviews if what they’ve received is what was ordered and notifies the vendor of any issues.

Three-Way Matching

Three-way matching is a verification process that accounts payable teams use to ensure that they are paying the correct amount and for the correct items. The process compares receipts/packing slips against the purchase order and invoice.

If all the information matches, then the invoice can be paid. If there is a discrepancy on the invoice or receipt, the vendor is asked for clarification or a correction to the invoice. This will follow an invoice dispute management process.

Discrepancies should be rectified as soon as possible to avoid late payment charges, production delays, or damage to supplier relationships.

Invoice Approval and Payment

Invoices that pass three-way matching are approved for payment. Payment is issued to the vendor via the payment information provided on the invoice.

Ideally, such payments are made with the goal of capturing early payment discounts and other incentives while avoiding late payment fees.

Using AP Automation software as part of a procurement software suite can speed up the payment process and capture more early payment discounts. It also helps solidify positive vendor relationships when payments are consistently made early or on time.

Accounting Records Update

Completed orders are recorded in the company’s books, and all documents related to the transaction are securely stored in a centralized location.

When using procurement software that integrates with your accounting software or ERP, this happens automatically and shouldn’t require any extra work from either accounting or procurement.

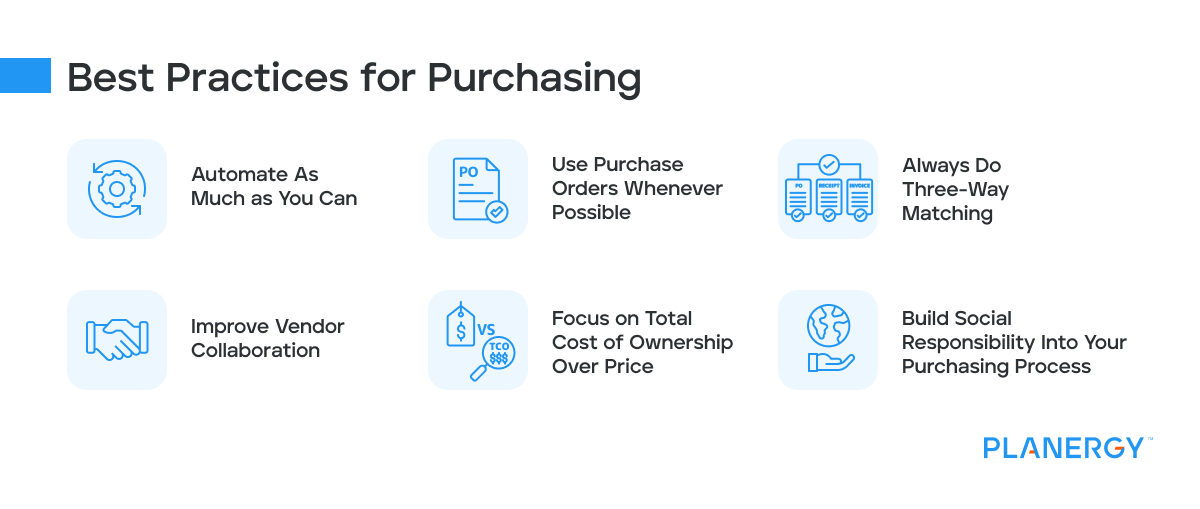

What Are the Best Practices for Purchasing?

Following a set purchasing process is helpful, but it doesn’t solve all of your procurement headaches.

To level up your purchasing process into a well-oiled machine, it’s helpful to follow the best practices laid out below.

Automate As Much as You Can

Manual and paper-based workflows are not sufficient for companies that want a streamlined purchasing process and healthy supply chain.

Adding automation at each step of the process eliminates many of the headaches that these outdated methods have traditionally caused.

Using a modern procurement solution to automate as much of the purchasing process as you can provides the following benefits:

- Eliminates waste and expense from paper workflows and storage

- Significantly reduces time-consuming, high-volume tasks

- More accuracy, speed, and consistency

- Reduced human error

- Better ability to capture early payment discounts and avoid late payment fees

- Speeds up the approval process for requisitions, POs, and invoices

Automation isn’t just about cost savings or reducing labor, it frees your staff up to work on more meaningful tasks, creating a flywheel effect of value creation as people find better ways to use their time.

Use POs Whenever Possible

It can be tempting to allow teams to make purchases on company credit cards without a formal PO, especially for small purchases. However, using a PO safeguards your business.

Once it is signed, the PO becomes a legally binding document that ensures the seller will provide the goods or services being purchased.

Also, using POs helps out later in the procurement cycle. When it’s time for payment the PO can be used to verify that payment is for exactly what was ordered as part of the three-way matching process.

Always Do Three-Way Matching

It can also be tempting to ‘just pay the invoice’ when dealing a stack of invoices to sort through. Creating policies where invoices are paid below a value threshold can save time but will leave you open to accounts payable fraud just like respected companies like Google and Facebook.

It’s highly recommended to always match the invoice against the purchase order and receipt. This ensures that you’re paying the correct price, not paying a duplicate invoice, and are paying for the correct items.

Three-way matching is much easier when procurement software keeps track of invoices, purchase orders, and receipts in a central location.

PLANERGY’s accounts payable system automatically matches invoices and purchase orders, which means you can manage by exception and save time while ensuring your invoice payments are correct.

Improve Vendor Collaboration

Your best vendors aren’t just suppliers; they’re partners and stakeholders in your success.

If you succeed, they succeed with you. By working closely and collaborating with them, you can help each other grow your businesses.

Consider how vendors can help you:

- Discover new markets

- Develop innovative new products with better raw materials

- Further streamline your workflows through contracted services

- Boost your bottom line with better pricing terms and exclusive agreements

Don’t just think about how your vendors can help you, but how you can help them. The best vendors are thrilled to have you as a customer and excited about the growth opportunities that you can achieve by working together.

Focus on TCO Over Price

The price isn’t the only cost behind a purchase. There can also be other costs such as maintenance, training, labor hours, and other items associated with making a purchase or investment.

Shifting your perspective to the total cost of ownership (TCO), which considers all of the expenses related to owning something rather than just the price tag, can change the way your procurement function makes decisions.

Considering purchases and their related costs and benefits throughout their entire lifecycle can help you create more long-term value.

Build Social Responsibility Into Your Purchasing Process

Consumers take social and political issues seriously when considering their purchases—and so should your business.

Responsible sourcing and having a focus on ESG (environment, social, and governance) in procurement is not just about complying with environmental or labor regulations, but protecting your reputation and showing your customers that you care.

When evaluating potential suppliers, pay attention to their compliance history and environmental and social reputation. If you choose suppliers that match your company’s ethics, you’ll minimize the chance of violating them.

How to Get The Best Value from Your Purchasing Process

Extracting the maximum value from the purchasing process requires care and skill—especially in a competitive and fast-moving global marketplace.

Along with following the best pratices above, using the right tools to automate and streamline the purchasing process will help you derive the most value.

Choosing a complete procure-to-pay software solution like PLANERGY can help you:

- Standardize processes for every purchase

- Reduce labor through automation

- Create more value at every step of the process

- Speed up your approval and purchasing flows

- Help you build better supplier relationships

- Improve spend visibility and reporting

- Identify savings opportunities with spend analytics

- Automate three-way matching and invoice processing

Having a solid purchasing process and reliable procurement software does more than just get solve your immediate purchasing needs.

It adds value, savings, sustainability, and greater productivity to your overall business.